Search

From flash photography to factory explosions over 130 years – Michigan

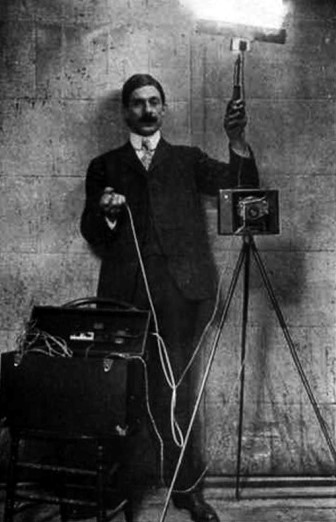

Somewhere in America in the late 1880’s a man stood with a camera facing his subject. In one hand he had a line of magnesium powder a-top a pole. A smile, a spark and a brilliant flash later he had captured a photograph (ref. 1). Fast-forward a century…

Explosion: In the early hours of the morning of May 2nd last year, a white glow was seen at the bottom of a magnesium scrap conveyor at an automotive MAGNESIUM parts manufacturer in Michigan (ref. 2). Then there were explosions in a tunnel at the bottom of the conveyor. There were also reports of one operator being injured by debris blasted from the plant and another of an employee being “thrown through the air on the way out of the building.

And another one…

Explosion: On October 22nd last year there was an explosion at a MAGNESIUM diecast manufacturing plant in Ontario, Canada (ref 3). Two people were struck by falling debris and suffered minor injuries, according to Global News, and structural damage was sustained to the facility.

Stonehouse Process Safety Commentary:

MAGNESIUM powder is incredibly useful today. Everything from aircraft parts to automotive components are made from magnesium, benefiting from the metal’s light weight and high strength giving a favorable strength-to-weight ratio. But the metal must be treated with great respect and thoughts of the photographer of yesteryear is the key to why.

If exposed to fire, thin sheets of magnesium can ignite in a matter of seconds. Even thicker castings can be ignited with enough heat over a few minutes. But finely divided magnesium, even as a layer, will explosively flash – as we know from our photography history lesson. But if that same magnesium powder is dispersed in the air, explosion will result with devastating rates of pressure rise (St-3 Classification). Many metals behave this way and great care is needed to avoid dust explosion.

There are even more dangers with metal powders that may surprise some. Some metal dusts can react with water to produce hydrogen – a gas that explodes so strongly when mixed with oxygen that it is used to propel spacecraft into orbit. And yet another danger arises when trying to extinguish a fire of burning metals. Many metals burn with such intense heat (perhaps 3000°) that the application of water results in instant explosive phase change from water to steam and decomposition… and another explosion results. There is clearly a lesson there for first-responders – and also indication of the risks introduced by inappropriately located sprinkler systems. [Metal fires are frequently left to burn or else smothered with, for example sand, where the fire is small.]

NFPA 652 has lots of general information about dust explosions, but metal dusts have their own standard, NFPA 484. At Stonehouse we have many years of experience advising companies control their fire and explosion risk. We have also looked at our fair share of incidents involving metal powders. Consult our metal industry web page https://stonehousesafety.com/markets-we-serve/metals-machining/#main for more information or speak to one of our process safety specialists. Call: 609 455 0001, Email: [email protected], Web: www.stonehousesafety.com.

References

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.