Search

The Importance of Specialist Electrostatic Hazard Analysis in Process Safety

In the realm of industrial process safety, static electricity is a deceptively simple phenomenon that can lead to devastating consequences. While general hazard analysis methods such as HAZOP (Hazard and Operability Studies), What-if, and Fault Tree Analyses are essential pre-start-up, they often do not provide sufficient detail for the elimination of electrostatic hazards. Electrostatic hazards require specialized expertise and separate analysis to ensure comprehensive risk management – expertise that is typically not available within processing or indeed within generalist process safety consulting companies.

This article emphasizes the importance of using specialist on-site electrostatic knowledge by examining a case history that highlights potential gaps in traditional hazard assessments. We believe these gaps can best be filled with specialist electrostatic hazard analysis and additional training for staff on this specific subject.

[This paper is an abridged version of a paper presented by Stonehouse at the American Institute of Chemical Engineers 2024 Spring Meeting and 20th Global Congress on Process Safety held in New Orleans, LA, March 24-28, 2024].

The Hidden Dangers of Static Electricity

Static electricity most commonly occurs when any two materials come into contact and then separate, causing an imbalance of electrons. This charge imbalance can lead to electrostatic discharges (ESDs) which, depending on the specific discharge type and energy content, can ignite flammable atmospheres. This risk is particularly high in industries dealing with flammable gases, vapors, and dusts. However, the dangers of static electricity are often overlooked or underestimated because its effects are not always immediately apparent.

Case Study: Biphenyl Dust Explosion

Incident Overview

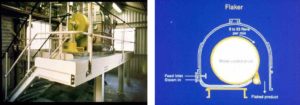

A stark example of the danger posed by static electricity is provided by an explosion that occurred during the production of biphenyl flake [ref 1]. The process involved pumping molten biphenyl into a flaker where it solidified on a cooled rotating drum and was then scraped off to form flakes. These flakes were collected in a pack-out hopper directly below the flaker.

Run-up to the Incident

For several months, the flaking operation experienced issues with dust escaping and flakes sticking to surfaces within the hopper and variations in product bulk density. Quality control occasionally found blackened biphenyl flakes in the final product. Additionally, the metal blade used for scraping the drum developed score marks on the drum, leading to its replacement with a fiber-reinforced thermoset resin blade. This change inadvertently increased the amount of dust generated during the process; the fiber blade was not as sharp as the metal blade.

The Explosion

On the day of the incident, the new blade had just been installed. A flash fire and explosion occurred within the flaker and hopper, causing a pressure build-up that was relieved through an inspection hatch that was routinely left open. Fortunately, there were no injuries, but production had to be halted for weeks to permit investigation and plant modification.

Investigation Findings

The investigation revealed that the increased dustiness, combined with the presence of biphenyl vapor at a temperature below its flashpoint, created a flammable hybrid mixture with a lower minimum ignition energy (MIE) than the dust alone. Electrostatic charge generation was high due to the intimate contact between the molten Biphenyl and the drum and the subsequent separation (scraping) of the solidified flakes. The flakes, with high volume resistivity (highly insulating), retained the generated charge long enough to accumulate significant voltage on the bulking flake, in the pack-out hopper downstream of the flaker. On-site measurements showed charging currents of about 70nA, leading to potential bulking brush/cone discharges in the hopper with energies up to 14mJ, well above the MIE of the biphenyl dust/ biphenyl vapor hybrid atmosphere.

Missed Warning Signs

Several early warning signs preluded the explosion:

- Persistent static electricity issues evidenced by dust/flake sticking to surfaces as well as variation in bulk product density.

- Occasional blackened flakes indicative of localized ignitions

- Increased dustiness following the blade change

These signs were not fully understood or acted upon in the period leading up to the incident. Furthermore, the hazard studies performed before start-up had not considered electrostatic cone discharges a potential source of ignition, nor had there been any appreciation that biphenyl vapor below its flashpoint could combine with biphenyl dust to create a hybrid dust/ vapor mixture with a lowered Minimum Ignition Energy than the MIE of the dust cloud alone.

Preventive Measures

The investigation suggested several possible measures to prevent such incidents:

- Reverting to a metal blade with better alignment to reduce dust generation

- Improved dust extraction to lower dust and vapor concentrations

- Applying electrostatic neutralizers to dissipate charge

- Explosion protection with improved explosion relief venting and isolation system

The Shortcomings of Traditional Hazard Analyses

Traditional hazard analysis methods like HAZOP and Fault Tree Analysis are designed to identify and mitigate a broad range of risks. However, they may not delve deeply enough into the specific behaviors and risks associated with static electricity. These methods might:

- Overlook the subtle situations conducive to static electricity build-up – e.g., flake-drum separation.

- Fail to quantify the potential energy (and therefore dangers) of electrostatic discharges accurately – e.g., risk of cone discharges.

- Not fully consider the unique interactions between materials that can generate static charges (triboelectrification).

Proactive Steps for Safety

Integrating electrostatic hazard analysis into regular safety protocols can prevent incidents before they occur. Key proactive steps include:

- Conducting comprehensive hazard analyses that include specific assessments for electrostatic risks either alongside traditional hazard analyses – or as separate electrostatic hazard assessment.

- Implementing robust safety measures such as proper bonding and grounding, using materials that minimize static generation, and maintaining regular safety equipment checks.

- Providing ongoing training to help employees identify and mitigate electrostatic hazards. Many incidents caused by static electricity exhibit ‘early warning signs’ which, if acted upon, can prevent incident.

Conclusion

Static electricity is a potent hazard in industrial settings involving flammable substances. The biphenyl dust explosion case study illustrates the severe risks posed by electrostatic discharges. Traditional hazard analysis methods did not provide sufficient coverage for these risks, underscoring the need for specialist electrostatic hazard analysis.

By incorporating comprehensive electrostatic hazard assessments into your safety protocols, you can better protect your personnel and business. This proactive approach includes detailed electrostatic risk assessments, targeted mitigation strategies, continuous monitoring, and employee training. Ultimately, understanding and addressing electrostatic hazards through specialized analysis can prevent catastrophic incidents, ensuring a safer industrial environment.

[Ref. 1] Information and diagrams courtesy of Institution of Chemical Engineers, Rugby, UK

Next Steps

For more information and to learn how Stonehouse can help safeguard your operations from electrostatic hazards, contact us today. Our specialized expertise in electrostatic hazard analysis onsite electrostatic measurements, and humidity-controlled laboratories can ensure your processes are safe and compliant. Reach out now to take the first step towards enhanced safety at your facility. Learn more electrostatic hazards here.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.