Search

SHRINK Your Classified Hazardous Areas to Reduce Risk (and save money)!

Maybe you’re operating with existing Classified Hazardous Areas at your facility or maybe you are modifying plant or building new facility. In all cases it’s worth challenging the extent of your Hazardous Areas. The reason is simple: Reduced Classified Areas mean improved control of flammable atmospheres, and any possible reclassification from Division 1 to Division 2, for example, means less onerous (and less costly) requirements for cables, conduits, enclosures, motors, etc. Your maintenance will be less too. Simple, right? Well, yes, it is – if you have a good understanding of Hazardous Area Classification and know the methods available to reduce your Classified Hazardous Areas.

Read on and get under the hood of Hazardous Area Classification (HAC) to see how it can be done in practice…

Starting Point

All the guidelines of the National Electrical Code (NEC/ NFPA 70), NFPA 497 (if area has flammable vapors and gases), and/or NFPA 499 (if area has combustible dust) have been followed. Perhaps you’ve just had a Hazardous Area Classification (HAC) prepared, or maybe you are wondering if there is any way of controlling the high costs of working with your current Hazardous Area Classification?

If the relevant codes (above) have been followed, then areas of your plant will now be classified as follows:

- By Class I or II, or both depending on the type of flammable atmosphere – gas/vapor and/or dust, and

- By likelihood of the presence of flammable atmosphere – either Division 1 where generally speaking, flammable atmosphere is more likely to exist, or Division 2 where flammable atmosphere is less likely to exist.

- By nature of the fuel (flammable atmosphere) – Groups A, B, C, or D for flammable gas, flammable liquid produced vapor, or combustible liquid produced vapor mixed with air and/or Groups E, F, or G for atmospheres containing combustible dusts.

- HAC is documented and drawings are created.

Specification of Electrical Equipment

It should be remembered that the main purpose of the HAC is to facilitate and guide engineers in the selection and installation of appropriate (safe) electrical equipment and wiring in hazardous areas, considering the properties of the flammable materials/atmospheres that will be present and how these materials are handled. Effectively in United States, HAC is a tool that enables engineers to specify, design, and install electrical equipment so it doesn’t become an ignition source.

The National Electrical Code is used to provide requirements for equipment for use in hazardous locations. Specifically, there is Article 501 (for areas that have flammable vapors/gases), Article 502 (combustible dusts), Article 503 (flammable fibers), Article 504 (Intrinsically Safe Systems), and Articles 510 to 516 for specific classified locations.

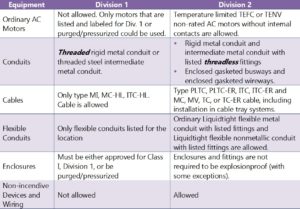

Even a quick glance through these articles shows that equipment and wiring requirements in Division 1 areas are significantly more severe and restrictive than those for a Division 2 where exactly the same type of flammable atmosphere might exist, albeit with a lower likelihood. The following table lists some of the differences in electrical equipment for Class I, Division 1 and Division 2 locations:

As you can see from this limited list of examples, requirements for electrical equipment and wiring are significantly more restrictive for Division 1 in comparison to Division 2 classified locations.

Reducing and downgrading Classified Areas

Now it is reasonable to ask – what can we do and how we can change our process and practices so number and extent of Division 1 areas could be reduced, re-classified as Division 2, and could Division 2 areas be reduced in size, and in some cases be re-classified as non-hazardous? Should we go back, revisit HAC and see if existing processes and practices could be changed? And it is not only about Hazardous Area Classification – improved control of flammable atmospheres makes the entire operation safer, so there is a reduced chance that ignition can occur due to the presence of non-electrical ignition sources – electrostatic discharges, mechanical sparks, hot surfaces, etc.

Codes, standards, and best industry practices provide many ideas on how this could be accomplished through better control of flammable atmospheres.

Here are some ways of reducing extent and possible downgrading classified hazardous areas:

- Improve containment. Provision of impenetrable partitions in Class I areas, and even penetrable partitions in Class II areas limit the extent of the flammable atmospheres. Also, quite often simple improvements in equipment maintenance and spill containment can make a significant difference.

- Improve ventilation and/or increase its availability in the process areas. Increasing level of dilution ventilation in Class I areas, and Local Exhaust Ventilation in Class II areas could significantly reduce likelihood and extent of flammable atmospheres allowing re-classification.

- Avoid open-air transfer (pouring) of flammable liquids and combustible dusts. This reduces the likelihood of dangerous spills and releases.

- Maintain process equipment containing flammables under negative pressure. This reduces the likelihood and extent of dangerous releases.

- Improve housekeeping technique and frequency. In Class II areas this can make a difference between having the area classified as Division 1, Division 2, or even unclassified.

- Use of Combustible Gas Detection Systems allows to reclassify many Class I, Division 1 areas as Division 2.

- When possible, consider:

- Replacing flammable liquids with others that have a Flash Point significantly higher than the process and ambient temperature.

- Using powders with median particle size higher than 500 µm (U.S. No. 35 standard sieve).

How we can help you

At Stonehouse we have specialist consultants for Classification of Hazardous Locations. They undertake Hazardous Area Classification (HAC) for some of our clients and revisit existing HACs for others who want revalidation or indeed are looking for ways that they can reduce/ downgrade already classified areas. Please contact us by calling us on 609-455-0001 or by completing our Contact Us page and we’ll arrange for you to have a complimentary discussion with one of our specialists to see how we can best help you.

References

- National Electrical Code (NEC/ NFPA 70),

- NFPA 497: Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

- NFPA 499: Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.