Search

EXPLAINERS: Understanding Classification of Hazardous Locations

In EXPLAINERS, we take our customary look at technical topics and try to simplify to get to the bottom of what’s really going on. This month it’s Hazardous Locations that get the treatment.

Hazardous Locations are key to avoiding fires and explosions caused by electrical equipment, so in this issue of Process Safety Dispatch, we are covering some important terms used in the Classification of Hazardous Locations, beginning with what we mean by a Hazardous Location!

In North American electrical installations, Hazardous Locations are defined by Classes, Divisions, and Groups to determine the level of safety required for equipment installed in such locations. We look at each of these terms in turn. [Note that the European classification system is a little different.]

What is a Hazardous Location? (Sometimes called a Hazardous Area)

A Hazardous Location is simply a designated area of plant where there is the possibility that an explosion or fire can exist as a result of the presence of flammable vapors or gases, combustible dust, or ignitable fibers or flyings. Hazardous locations are fully defined in the US National Electrical Code (NEC) but read on for more.

Stonehouse has a number of articles connected with Hazardous Areas Locations, see for example Hazardous Locations: From Davy Lamp to Flameproof Equipment or Hazardous Location Classification: Electrical Equipment in Flammable Atmospheres.

What are Classes?

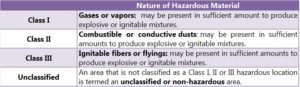

This is the easy part. In the Classification of Hazardous Locations, Classes define the nature of the hazardous material that may be present. Hazardous material can be in the form of a gas or vapor, a combustible or conductive dust or an ignitable fiber or flying, and this nature of the material links directly to Class. This can be more precisely defined in a table.

What are Groups?

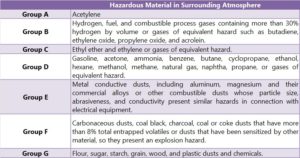

Group designations are used to selectively divide a Class into categories of material that have similar combustion characteristics. Groups are designed by the letters A through G. Groups A through D, are Groups for Class I, and E through G are Groups for Class II materials (see Table). Hazardous Materials groups can be presented in a table.

What are Divisions?

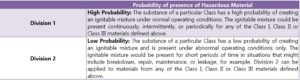

The decision to classify an area as hazardous should be based on the probability (or likelihood) that a flammable/combustible mixture could be present. Two Divisions are used to specify the likelihood of a flammable atmosphere being present.

Examples:

Gases or vapors

A Class I, Division 1 hazardous location is one where ignitable concentration of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors may exist under normal operating conditions.

Combustible dusts

A Class II, Division 2 location is one where combustible dust may occur due to abnormal operating conditions and may be dispersed in the air in sufficient concentration to create an explosive or ignitable mixture. There could also be powder build-up on electrical equipment that might be deep enough to prevent, by conduction, the safe dissipation of heat produced by the equipment.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.

We use cookies to help us enhance your experience on our website. By clicking “Accept,” you consent to our use of cookies. Read our Privacy Policy for more.