Search

Communication in Process Safety

Why it matters a lot, and what we are doing about it!

In every aspect of life–business or personal–communication defines us. It is how we get information from our heads out into the world for others to understand. If we don’t do a good job in defining our thoughts, the receiver of our information will not fully understand what we are trying to tell them. This is what happens all too often in the world of Process Safety, except the consequences of getting it wrong, multiply.

Texas City Refinery Explosion

On March 23, 2005, the BP refinery in Texas City, Texas, experienced one of the most severe refinery explosions in the U.S. history. The incident caused 15 deaths and over 180 injuries. The explosion occurred during the startup of an isomerization unit, where a distillation tower was overfilled with hydrocarbons, and a vapor cloud was ignited.

Communication Breakdown: In the Texas City refinery explosion, communication failures played a significant role in the incident’s escalation and tragic outcome. The U.S. Chemical Safety Board’s investigation into the event [Ref 1] revealed that there were recurring procedural deviations during startups of the unit involved, which were well known but not formally addressed or communicated in operational policies. This pattern of accepted procedural workarounds became the norm, rather than the exception, which contributed to the unsafe conditions leading up to the explosion.

Specifically, communication about the status and operation of the equipment was critically flawed. For instance, the control board operator made decisions based on incorrect instrument readings and was not adequately informed about the actual conditions within the process unit. This lack of clear, accurate communication was compounded by the absence of effective shift turnover communications, which should have included detailed logbook entries and explicit startup procedures. This failure in communication meant that crucial information regarding the operation status and safety concerns was not adequately relayed or documented, leading to unsafe operational practices.

Bhopal Tragedy

On December 2-3, 1984, the Bhopal Tragedy occurred at a pesticide plant operated by Union Carbide Corporation in India [Ref 2]. The incident, which is considered one of the world’s worst industrial disasters, was primarily caused by water entering a tank containing methyl isocyanate (MIC), triggering an energetic (runaway) chemical reaction. The incident resulted in thousands of deaths and serious injuries.

Communication Breakdown: A lack of clear communication about safety protocols and the condition of the plant’s equipment contributed significantly to the disaster. Important safety equipment and instrumentation was not operational, some was under maintenance, and the importance of this critical information was not adequately communicated/ appreciated by the operating staff. Additionally, the staff was not trained sufficiently to handle emergencies, highlighting a systemic failure in communicating safety standards and emergency procedures.

The incident underscored the necessity of robust communication channels and clear procedures in industrial settings, especially during critical operations like unit startups and shutdowns. These findings highlight the need for stringent management-of-change processes, proper training, and the implementation of safety management systems that ensure all operational information is clear, accessible, and correctly interpreted by all staff involved.

What are we doing about improving our Communication with you?

Procedural

At Stonehouse we perform a lot of PHAs (Process Hazards Analyses), DHAs (Dust Hazard Analyses) and EHAs (Electrostatic Hazard Analyses) alongside a whole host of specialist safety studies. We need to communicate with you a lot! We visit you, our client, at your facilities, we discuss processes and operations, we access our individual experiences, our digital knowledge banks, and our extensive library of process safety references, we analyze what we have seen, and we discuss our findings in person with you, our client. We prepare a tailored report which is internally peer reviewed for accuracy, clarity, and practicality. We might also discuss some aspects of the project internally amongst our own experts and again with our client to answer their questions. Our final report is then crafted and issued. But throughout all of this, we recognize that the language we use and the words we choose to convey meaning and intent are really important.

The Words we Use

Effective communication is a cornerstone of process safety and its management. With the examples we have presented above, we see that correct and clear communication can be the difference between safety and disaster. In our discussions with you and in the words that we choose for the recommendations in our reports at Stonehouse, we avoid ambiguity, making sure that if we do have to use words like “must”, “should”, “consider”, and “alternative”, we use them in such a way that they are helpful to our clients [Ref 3].

Here are a few thoughts on choice of words and how they can be interpreted:

- Shall: Taking the lead from NFPA standards, the word “shall” in a safety recommendation, usually indicates a need to conform to a code or standard requirement, and the applicable code or standard would be referenced in the recommendation. Clients need to consider the possible consequences of not resolving a “shall” recommendation (from an NFPA standard), since this could include cost penalties, production interruption, and damage to corporate reputation in event of a serious incident.

- Should: If we use the word “should” in safety recommendations, this usually indicates a need to conform to recognized and generally accepted good engineering practice and where such good practice is not included in a code or standard. Regulatory authorities could consider failure to implement a good practice as an incident cause, during an investigation. Thus, clients need to consider the possible consequences of not implementing a “should” recommendation.

- Consider: – If we use the word “consider” in a safety recommendation, this indicates that the Stonehouse consultant has used personal experience or the experience of peers to develop a suggestion for improving the safety of the client’s personnel, property, or operations. There may not be a reference to a document that would support the recommendation. The client has an option to accept or reject such a recommendation, after considering its practicality, feasibility, and consequences of not accepting the recommendation.

- Alternative: If we use the word “alternative” in a recommendation, it is a recognition that there may be other methods for achieving the objective(s) of a recommendation that may be more practical or feasible than the Stonehouse recommendation. Many codes and standards make similar statements concerning equivalency, such as “Nothing in this code is intended to prevent the use of systems, methods, or devices of equivalent or superior quality, strength, fire resistance, effectiveness, durability, and safety over those prescribed by this code”.

In response to requests from our clients, Stonehouse is following a semi-quantitative risk assessment for each of our recommendations, as summarized below:

- High risk (Priority 1): This would involve moderate to severe hazards of fire, flash fire, explosion, or toxicity and could occur several times during a decades-long life of the process.

- Moderate risk (Priority 2): This would involve minor to moderate hazards of fire, flash fire, explosion, or toxicity and could occur a few times during a decades-long life of the process.

- Low risk (Priority 3): This would involve minor hazards of fire, flash fire, or toxicity and could occur once or might not occur during a decades-long life of the process.

This approach to hazards analysis has enabled Stonehouse to identify where, in our opinion, the largest risks could occur and to prioritize our recommendations to prevent or minimize the identified hazards. Also, this prioritization may help the client with safety-work scheduling and resource allocation. However, the Stonehouse consultant usually does not suggest goal dates for implementation or resolution of recommendations.

Our Strategy for Clear Communication

To enhance the clarity and effectiveness of our communication with you in process safety, we make use of a robust peer review process where all reports that leave our company are checked for accuracy, clarity, and practicality by a second specialist within Stonehouse. The peer review process aims to ensure that our reports:

- Use direct and mandatory language where warranted. Ambiguous terms would be replaced with direct, action-oriented language. For instance, we prefer “must” rather than “should” to indicate code or standard requirements.

- Define all terms clearly. Where terms need to be used, their meanings should be clearly defined in the report we prepare for you. For example, if “adequate control of the hazard” is used, we aim to specify what policies, procedures, practices, standards, or conditions make such process control “adequate”.

- Refer to pertinent NFPA or other standards where these add to the report and its intent. Such references can also provide further reading to aid client understanding and provide context.

- Avoid overly technical jargon. While technical language is sometimes necessary, it should be explained or simplified if the reader is likely not familiar with the terminology. This ensures that the communication is accessible to all relevant parties, not just experts. Acronyms are spelled-out at the first use, in a report.

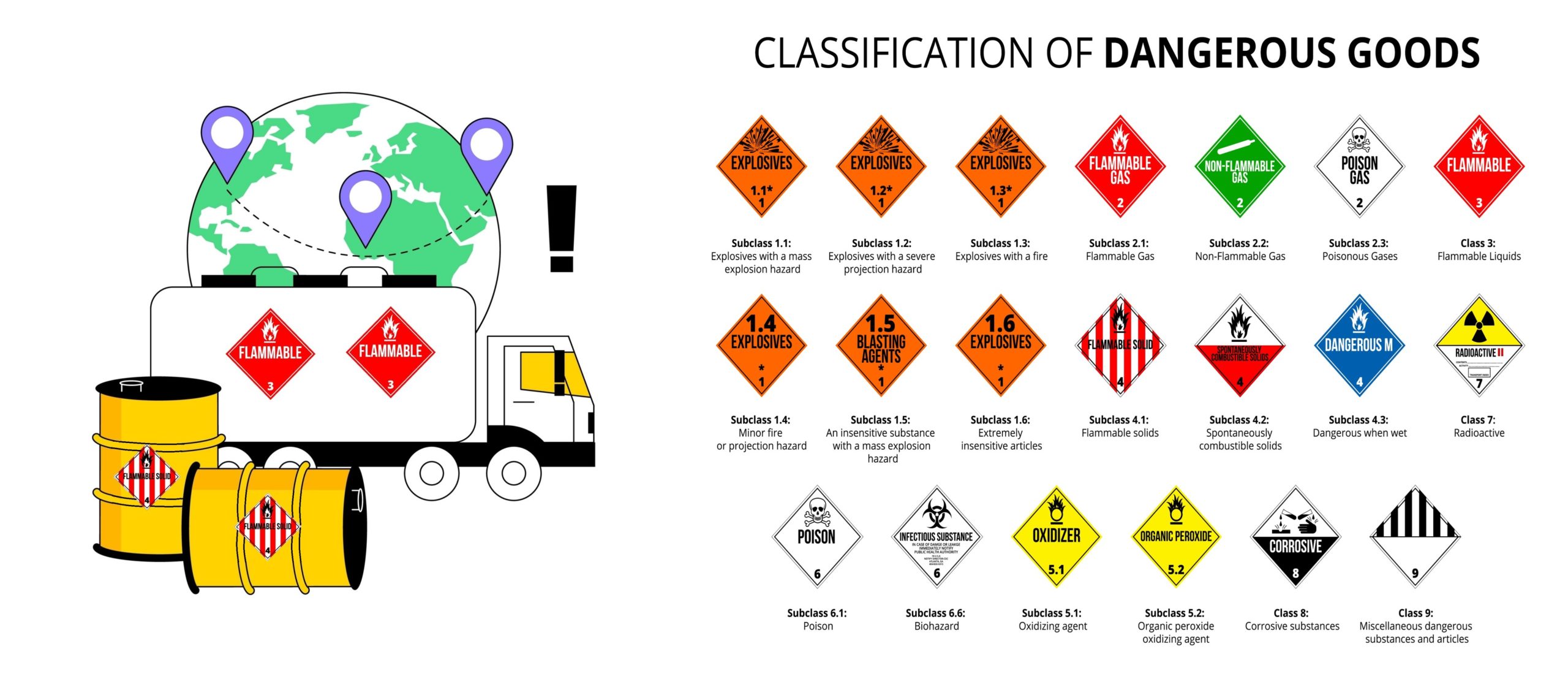

- Include visual aids where needed. Diagrams, flowcharts, photographs, and other visual aids can help clarify complex processes or instructions, reducing reliance on potentially ambiguous textual descriptions.

Conclusion

Clear communication is critical in process safety and its management. By eliminating ambiguity and ensuring that all instructions are direct and easily understood, organizations can significantly reduce the risks associated with misunderstandings or misinterpretations of safety procedures. At Stonehouse, we are always looking for ways to improve the way we communicate with you, our client. We aim for simplicity and clarity and lack of ambiguity whenever we can, and we have checking and peer review processes for all the reports that leave our organization.

References

Ref 1: US Chemical Safety and Hazards Board Investigation Report, “Refinery Explosion and Fire”, Report No 2005-04-I-TX, March 2007

Ref 2: The Internet, Wikipedia “Bhopal Disaster”.

Ref 3: Cave, D, “The Importance of Language in a Dust Hazard Assessment”, in Powder & Bulk Solids, June 2024.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.