Search

How to Prevent Fires and Explosions in Powder Drying (Part 2): Laboratory Testing

In the last issue of Process Safety Dispatch, we looked at how thermal instability (self-heating) in powder drying can lead to fires and explosions, often due to insufficient data on the thermal behavior of the powder [Ref 1, Ref 2].

In Part 2, we focus on how to identify and mitigate these risks through practical laboratory screening. The aim is simple: to avoid self-heating incidents by confirming that powders are thermally stable under the chosen drying conditions – before scaling up to production.

Why Thermal (Self-Heating) Testing Matters

Many drying operations assume powders are thermally stable based on limited (small-scale) test data and experience. But under certain conditions, such as heated powder accumulation in bulk or prolonged contact with hot surfaces, some powders can self-heat, decompose, ignite, or even explode.

Basic thermal characterization tools like Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are helpful for baseline thermal data, but they typically use very small samples in closed environments with fast scan rates. These techniques can miss critical self-heating behavior seen in full-scale drying operations, particularly where large powder masses, hot airflow, or longer residence times are involved.

Three Core Tests for Realistic Screening

To reflect real-world drying processes, we use three thermal stability screening tests. Each one is designed to model the heat transfer and airflow conditions found in specific dryer types [Ref 3].

1. Bulk Powder Test – Static Drying and Storage Conditions

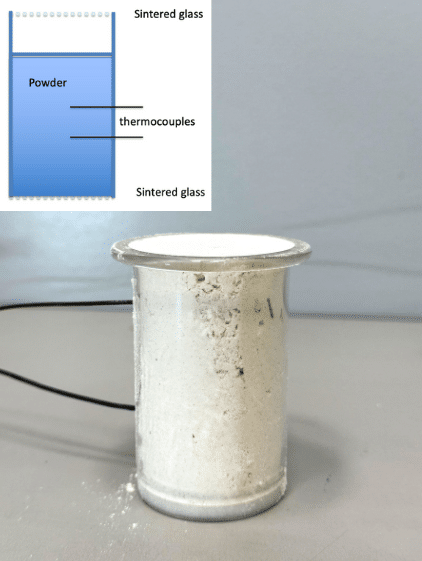

Bulk Powder Thermal Stability Test (80mm length x 50mm dia, ramp rate 0.5 degC/min)

Relevant to: Tray dryers, drum dryers, packed bed dryers, bulk packaging, hoppers, silos

The Bulk Powder test evaluates thermal stability when powders are heated or reside in bulk form, simulating conditions where material may accumulate during drying and/or subsequent storage and packaging. A representative sample (about 200cc) is placed in a test cell and heated slowly (typically 0.5°C/min).

This test is the first crucial screening test for identifying whether a powder will self-heat when left in a static mass, such as in the base of a dryer, bins, hoppers, silo or even in a full bag of hot material after drying. The relatively large sample size, slow temperature ramp rate, and air flow conditions simulate well those found in tray dryers, drum dryers, packed bed dryers, bulk packaging, hoppers, silos. They therefore give a good indication of onset self-heating temperature and runaway behavior. To achieve more precision the test can be performed isothermally. The duration of such Isothermal testing will be based on actual drying time of the process being investigated and, depending on screening test results, may not be necessary, saving time and cost.

2. Aerated Powder Test – Fluidized and Airflow Drying Conditions

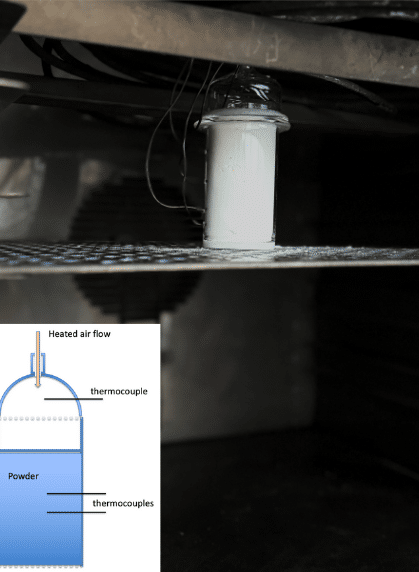

Aerated Powder Thermal Stability Test (80mm length x 50mm dia, ramp rate 0.5degC/min)

Relevant to: Fluidized bed dryers, pneumatic dryers, flash dryers

This test simulates conditions where powders are fluidized or transported in hot air. The test sample is fluidized with heated air, and both the powder and air temperatures are ramped together. It captures thermal hazards that arise in oxidizing environments, especially where airflow (and therefore more oxygen) is available in drying.

This test can be operated as a screening test where temperature is slowly ramped up at 0.5°C/min or for more precision it can be run isothermally. Just like in the Bulk Powder Test, the real benefit of the test lies in its ability to simulate conditions inside fluidized bed dryers, pneumatic dryers, or flash dryers. Excess air availability to powders can have the effect of cooling the powder, making exothermic decomposition and thermal runaway less likely, but with some powder, excess air can alternatively lower exotherm runaway temperatures due to increased oxygen availability. Testing is the only way to explore this.

Many organic powders (e.g., milk powders, APIs) and metal powders (e.g., aluminum, magnesium) are highly combustible and can become particularly hazardous when sufficient or excess air is available, providing ample oxygen to support vigorous combustion or explosion.

3. Powder Layer Test – Surface Heating and Buildup Risks

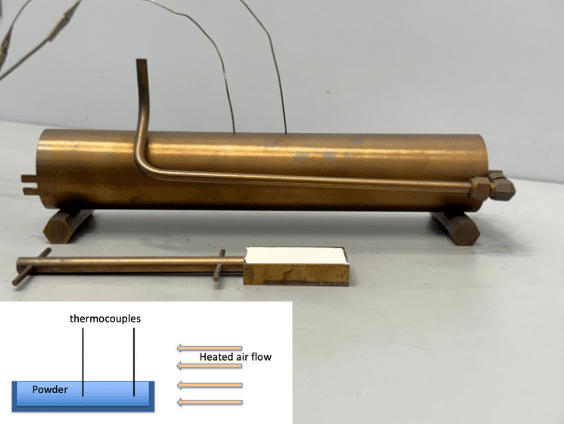

Powder Layer Thermal Stability Test (75mm length x 40mm dia, 15mm powder layer, ramp rate 0.5degC/min)

Relevant to: Cross-flow, tray and band dryers

Powders that appear stable in bulk or aerated conditions may still be hazardous when spread in a thin layer. The Powder Layer test assesses how powders behave when exposed to hot surfaces, mimicking trays, belts, and wall deposits in dryers.

A layer is spread on a tray and heated in air, with self-heating and ignition closely monitored. This test helps prevent localized decomposition, surface fires, and dryer wall ignition, all of which are common root causes of powder dryer incidents. Again, this test can be operated as a screening test where temperature is slowly ramped up at 0.5°C/min or for more precision it can be run isothermally.

Additional Testing Options: Grewer Oven, Basket Tests

The Grewer Oven test is a dynamic thermal screening method where powders are heated in a controlled stream of air. It is ideal for identifying materials that exhibit self-heating under oxidative conditions, serving as an effective early warning tool for potential hazards. This test is sometimes an alternative to the aerated powder tests described above, although sample size is smaller.

For large-scale simulation and for the greatest accuracy, basket test thermal simulations at different basket volumes can be performed. These tests study heat retention with long heat duration and with volume scaling effects. These tests are especially helpful when dealing with large powder volumes, like in silo storage or big bags (FIBC), or even in dryer bottoms with long duration exposure scenarios and when very accurate decomposition and thermal runaway onset temperatures are required.

From Lab to Plant: Interpreting the Data

Thermal testing is not just about identifying risks – it’s about defining safe operating parameters. Based on lab results, it’s possible to adjust and specify:

- Drying temperatures to stay below decomposition thresholds

- Residence times to avoid prolonged heating

- Dryer design to prevent powder buildup or promote heat dissipation

- Atmosphere control (e.g., nitrogen instead of air) for reactive powders

Where self-heating is detected, mitigation strategies – such as temperature control, inerting, and fire and/or explosion protection – is often required.

A Smarter Approach to Powder Drying Safety

The combination of Grewer, Bulk Powder, Aerated Powder, and Powder Layer tests gives targeted insights into thermal behavior under actual drying and handling conditions. When supported by tools like DSC, TGA, Grewer Oven, and (for increased precision) basket tests and isothermal techniques, this approach forms a powerful basis for safe process design in powder drying.

At Stonehouse Process Safety, we specialize in powder safety testing and consulting, helping our clients prevent fires and explosions through robust thermal screening.

If you’re drying powders in any industrial process, make sure you test before you dry and package.

Conclusion: A Comprehensive Strategy for Safe Powder Drying

Over the course of this two-part series, we have explored why thermal instability (self-heating) in powders is a serious but preventable hazard in industrial drying operations. We have seen how:

- Self-heating, decomposition, and runaway reactions have led to real-world industrial fires and explosions.

- Thermal characterization testing is essential for predicting hazardous behavior before powders are scaled for drying in production.

- The Grewer oven, Bulk Powder, Aerated Powder, and Powder Layer (Air-Over-Layer) tests provide critical insights into powder stability under different drying and subsequent storage/packaging conditions and test results can be used to set drying and storage/packaging conditions that prevent thermal runaway.

By implementing screening methods and more precise testing when needed, it’s possible to:

- Establish safe drying temperature limits whatever your dryer type.

- Optimize drying residence and storage times after drying to prevent decomposition.

- Mitigate fire and explosion risks through proper process controls.

At Stonehouse Process Safety, we specialize in thermal hazard assessments and process safety consulting to ensure that powders can be safely dried.

If your operation involves industrial powder drying, we strongly recommend considering self-heating hazards and performing thermal stability testing before full-scale production.

Contact Stonehouse today to learn more about our comprehensive powder safety testing services.

References

Ref 1: Stonehouse Process Safety Dispatch, April 2025: https://stonehousesafety.com/the-hidden-hazard-of-thermal-instability-in-powders-preventing-fires-and-explosions-in-drying-operations-through-laboratory-testing-part-1/

Ref 2: Henry L. Febo Jr, Processes for Drying Powders – Hazards and Solutions, Chemical Engineering Transactions VOL. 31, 2013

Ref 3: John Abbott, “Prevention of Fires and Explosions in Dryers,” 2nd Edition, The Institution of Chemical Engineers, 1990

Picture Source: https://unsplash.com/photos/a-close-up-of-a-fire-with-a-black-background-H2dxK5YhVsc

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.