Search

Which Risk Assessment Technique for me?

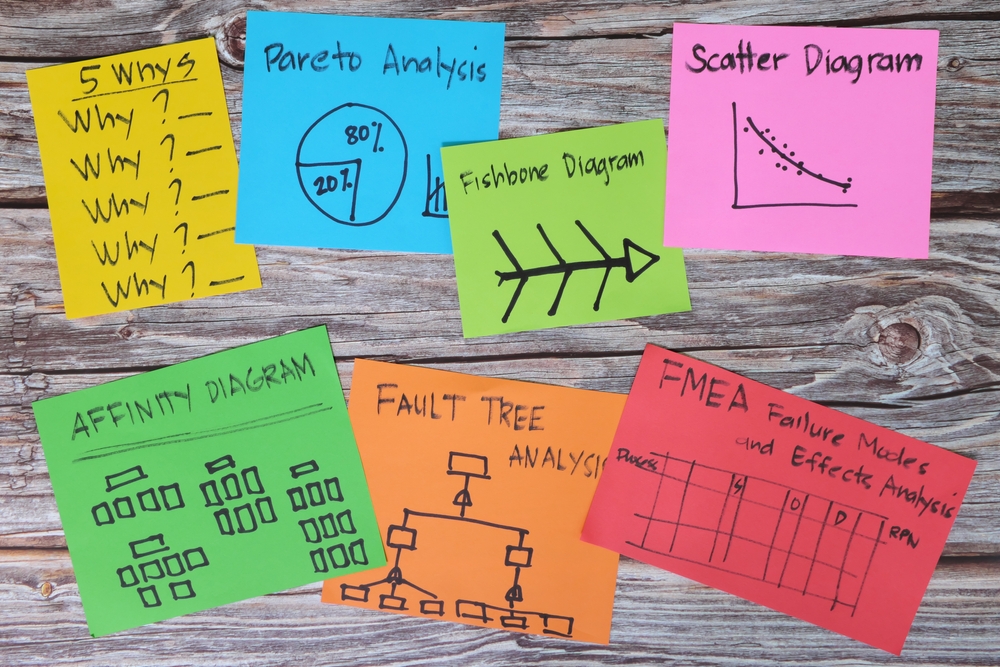

In the daring quest to identify, evaluate, and tame potential hazards lurking within industrial processes, risk assessment techniques come to the rescue. These techniques have a critical part to play as part of your Process Safety Management journey. In this opinion piece we review six widely used risk assessment techniques: What-if analysis, Hazard and Operability Study (HAZOP), Fault Tree Analysis (FTA), Quantitative Risk Assessment (QRA), Bowtie analysis, and Safety Integrity Level (SIL) analysis. By examining process safety situations where each technique excels or may fall short, we can gain a deeper understanding of their strengths and limitations, and perhaps help you in selecting the most appropriate technique to choose for your process risk assessment.

But whichever technique you select, we would welcome a call from you for a free of charge chat to talk you through the options. You might like us to run a risk assessment for you, or we might add value by providing specialist technical input to your own risk assessment. But even if you do it entirely in-house, we’re happy in the knowledge that we’ve been a sounding board for you to help you select the best technique for you.

So, what’s it to be – the daring What-if analysis, the cunning HAZOP, the meticulous FTA, the quantitative QRA, the agile Bowtie analysis, or the vigilant SIL analysis? Let’s find out….

What-if Analysis:

At Stonehouse, one way or another, What-if is omnipresent in our work; In some ways, What-if questions come from experience, and our consultants are generally long-experienced and have seen things before.

What-if analysis is an informal brainstorming technique that encourages critical thinking and hypothetical scenario exploration [Ref 1]. It is most effective during the early stages of process design or modification when detailed data may be limited. This technique involves posing questions such as “What if a chemical spill occurs during transfer?” and analyzing the potential consequences. What-if analysis allows for a qualitative examination of hazards and their potential impacts. It is well-suited for initial hazard identification and brainstorming, where a systematic approach may not be feasible.

For example, in a pharmaceutical manufacturing plant, a What-if analysis can be conducted to identify potential hazards associated with the process. The team might explore scenarios like “What if there is cross-contamination between different drug formulations?” or “What if the temperature control system fails during a critical process step?” Such analysis helps in uncovering potential hazards and assessing their consequences, allowing for early risk mitigation.

However, the What-if analysis may not provide a comprehensive understanding of complex systems or quantify risks accurately. Its subjective nature and reliance on the team’s experience and expertise can lead to biases or overlooking certain hazards.

Hazard and Operability Study (HAZOP):

HAZOP is one of the most common techniques where our clients request assistance from Stonehouse; we typically provide an experienced HAZOP chair or sometimes bring in one of our specialists to bring their technical knowledge and fresh eyes to maximum effect.

HAZOP is a systematic approach that involves a multidisciplinary team scrutinizing each process element to identify potential hazards and operability issues [Ref 2]. This technique excels at identifying hazards associated with deviations from the intended design or operating conditions. HAZOP follows a structured methodology, breaking down the process into nodes and examining them for possible deviations.

In an oil refinery, for example, HAZOP can be used to analyze the process elements involved in the refining of crude oil. The team can explore deviations such as abnormal temperatures, pressure fluctuations, or incorrect valve positions. By systematically examining each node, potential hazards can be identified, such as equipment failure, leaks, or fires. HAZOP allows for a detailed analysis of the process and enables the team to develop risk control measures to mitigate identified hazards.

However, HAZOP’s effectiveness relies on the expertise and experience of the team conducting the study (which is where Stonehouse may have a part to play). It may not be the most efficient technique for processes with simple operations or when time constraints make a detailed examination impractical.

Fault Tree Analysis (FTA):

FTA is a deductive, top-down technique that analyzes the probability of an undesired event occurring by constructing a logical diagram tracing all possible paths leading to the event [Ref 3]. It is beneficial for investigating specific events and understanding the critical factors contributing to their occurrence. FTA follows a structured approach, starting with the undesired event and breaking it down into contributing causes.

For example, in a nuclear power plant, FTA can be employed to analyze the event of a reactor meltdown. The analysis would identify the contributing factors, such as coolant failure, control system malfunctions, or operator errors. By breaking down the undesired event into its causes, FTA provides insights into the critical components or events that contribute to the occurrence of the undesired event. This allows for the development of targeted risk control measures to prevent or mitigate such events.

However, FTA requires detailed data and can be time-consuming, especially for complex systems. It may not be suitable for processes where event scenarios are difficult to define or quantify, or when detailed data is lacking.

Quantitative Risk Assessment (QRA):

QRA employs mathematical models and available data to quantify risks associated with process activities [Ref 4]. It considers various factors, including process hazards, equipment failure probabilities, and consequence analysis. QRA provides valuable insights by quantifying risk levels in terms of frequencies and potential impacts.

In an offshore oil rig, for example, QRA can be used to estimate the likelihood and consequences of a blowout event during drilling operations. By considering factors such as the probability of well control equipment failure, environmental conditions, and response capabilities, QRA quantifies the risk associated with a blowout event. This enables decision-makers to evaluate the effectiveness of existing control measures, such as blowout preventers, and implement additional risk reduction measures if necessary.

QRA is well-suited for processes where a quantitative understanding of risks is essential for informed decision-making. However, QRA heavily relies on accurate and comprehensive data, which may be challenging to obtain in some cases. Additionally, the complexity of mathematical models and data requirements can make QRA a resource-intensive and time-consuming process.

Bowtie Analysis:

Bowtie analysis is a visual risk assessment technique that represents potential causes, preventive measures, and consequences of a hazardous event [Ref 5]. It enhances risk communication and facilitates proactive risk management. Bowtie analysis combines elements of both qualitative and quantitative risk assessment.

As an example, in a manufacturing facility handling flammable chemicals, a bowtie diagram can be constructed to depict the causes of a fire event, preventive measures such as fire alarms, emergency response plans, and potential consequences such as injuries or property damage. Bowtie analysis provides a clear visual representation of hazards, controls, and consequences, allowing stakeholders to understand the critical risk scenarios and associated control measures. It enables the organization to proactively identify gaps in their risk management strategies and take appropriate actions to strengthen their safety measures.

Bowtie analysis is effective in situations where clear visualization of hazards, controls, and consequences is necessary for effective risk communication. However, it may not provide detailed quantitative risk assessments and can be subjective based on the interpretations of the team conducting the analysis.

Safety Integrity Level (SIL) Analysis:

SIL analysis is a specific technique used in industries with safety instrumented systems (SIS) to reduce risks [Ref 6]. It assesses the reliability and effectiveness of safety instrumented systems’ components to achieve required risk reduction targets. SIL analysis evaluates the probability of failure on demand (PFD) for each safety function within the SIS.

Example Application: In a chemical plant, SIL analysis can be utilized to assess the safety devices’ performance, such as emergency shutdown systems. By analyzing the probability of failure on demand for these safety systems, the organization can ensure that they meet the required safety integrity levels. SIL analysis provides a systematic approach to evaluate and verify the effectiveness of safety instrumented systems in reducing risks to an acceptable level.

SIL analysis is well-suited for evaluating the performance of safety systems in mitigating risks. However, its application is limited to industries where safety instrumented systems are prevalent. It may not be as applicable in industries where safety systems are not commonly employed, or when the focus is on broader risk assessment beyond safety systems.

Conclusion:

The selection of an appropriate risk assessment technique in process safety depends on various factors, including skill and experience of the assessors, process complexity, available data, desired level of detail, and specific objectives. Each technique has its strengths and limitations, and their effectiveness varies depending on the process safety situation at hand.

What-if analysis and HAZOP are effective for preliminary hazard identification and brainstorming, while FTA and QRA provide detailed analysis and quantitative risk assessments. Bowtie analysis enhances risk communication through visual representation, and SIL analysis focuses on evaluating the performance of safety instrumented systems.

Stonehouse can bring into play the many years of industry specific experience of our consultants to help you with your Process Hazard Analysis, whatever the type. Just pick up the phone and give us a call on 609-455-0001 – or complete our enquiry form here.

References:

Ref 1: Sperber, W. H. (2002). Hazard Analysis Techniques for System Safety. John Wiley & Sons.

Ref 2: Dunjó et al, Hazard and operability (HAZOP) analysis. A literature review, September 2009, Journal of Hazardous Materials 173(1-3):19-32, DOI:10.1016/j.jhazmat.2009.08.076

Ref 3: Haasl, D F; Roberts, N H; Vesely, W E; Goldberg, F F, ‘Fault tree handbook’, 1981-01-01, Nuclear Regulatory Commission, Washington, DC (USA). Office of Nuclear Regulatory Research.

Ref 4: Vose, D. (2008). Risk Analysis: A Quantitative Guide (3rd ed.). John Wiley & Sons.

Ref 5: Anderson, D et al. The Use of Bow Ties in Process Safety Auditing. IChemE Symposium Series No161, 2016

Ref 6: IEC 61511-1:2016. Functional Safety – Safety Instrumented Systems for the Process Industry Sector – Part 1: Framework, Definitions, System, Hardware and Software Requirements.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.