Search

Pharmaceutical Production: Lessons Learned from a serious Flash Fire Incident and its Investigation

Pharmaceutical Production: Lessons Learned from a serious Flash Fire Incident and its Investigation

Pharmaceutical manufacturing often operates in a complex realm where safety reigns supreme, protecting both workers and the integrity of the production process. But sometimes it is not complexity that obfuscates the path to safe operations.

In this issue of Process Safety Dispatch, we look at a flash fire incident that took place during a routine sieving operation, which serves as a stark reminder of the potential hazards that can arise within even the simplest and most well-established process. We delve into the incident, its investigation, findings, and the subsequent learnings, emphasizing the crucial role of dust explosion test data AND the importance of the expert application of industry standards and best practices in preventing dust explosions and flash fires.

The Incident: Igniting the Unknown

For ages, uneventful sieving operations had been the norm at the pharmaceutical company. However, a seemingly minor change in the process would lead to a major incident. That change: a dustier powder batch was introduced for sieving, creating an immediate challenge regarding dust control.

Same Powder, Just More Dust!

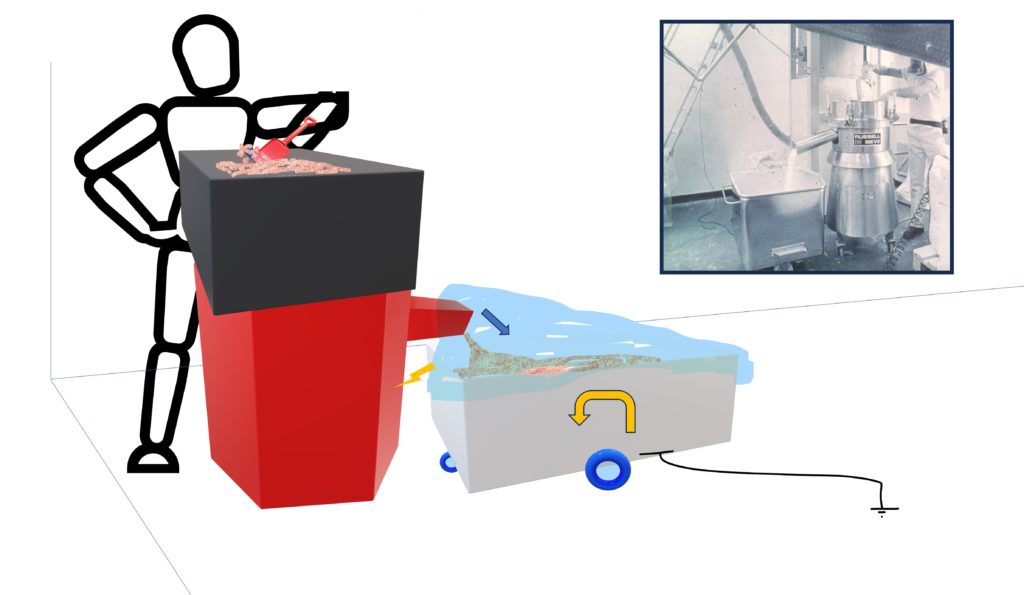

To mitigate dust escape, the operators used their initiative and covered the receiving bin and discharge chute of the sifter with a plastic sheet; an act that would have unintended consequences.

Following the operator’s routine application of a grounding clamp to the side of the receiving bin (electrostatic control measure) and with ad-hoc plastic dust sheet in place, the operation commenced. In a chilling turn of events, a flash fire erupted within the bin. The operator promptly left the room to avoid the escalating situation – and remarkably escaped unscathed. But a fire was developing in the bin and the black smoke that rose to the ceiling began descending, signaling an impending crisis. The quick-thinking operator returned to the sieving room and successfully extinguished the fire, preventing a far more serious outcome.

There is little doubt that the initial flash fire and subsequent combustion in the receiving bin began with the ignition of dispersed dust; a flash fire had occurred in the bin. Dust explosion testing confirmed this. A simple Go/No-Go Explosibility Screening test of the powder fines was performed that proved the dust to be combustible – and therefore capable of dust explosion/ flash fire. Furthermore, a Fire Train (Burning Rate) test on the powder confirmed the ability of the bulked powder to support the ensuing fire.

The Ignition Source: Lab Tests and Industry Standards

Ignition Sources: The initial incident investigation ruled out several potential ignition sources. The powder was tested in the laboratory for its thermal stability (self-heating) and Minimum Auto-Ignition Temperature (MAIT). It was found to be thermally stable as a layer/accumulation and not sensitive to auto-ignition as a dust cloud by a heated surface or by frictional/grinding sparks that might be caused by failure of vibrating components of the sifter. Furthermore, all electrical equipment in the area was checked; given the powder’s Minimum Auto-Ignition Temperature and equipment temperature rating, electrical equipment was found to be correctly specified for the Classified Hazardous Location in which it was installed. Furthermore, close inspection of the sifter found it to be in proper working order. So, we could eliminate powder self-heating, mechanical failure, and electrical equipment as potential sources of ignition. There was however one remaining ignition source – static electricity – as the most credible culprit.

Industry standards, such as NFPA 77: Recommended Practice on Static Electricity, provide comprehensive guidance on control of static electricity hazards in industrial processes, including pharmaceutical manufacturing. This standard recommends measures for controlling static electricity, including grounding and bonding which are pivotal in preventing incidents like the flash fire described here.

The sieved powder was further tested in the laboratory to determine its electrostatic properties. The powder was found to readily generate static charge in contact with stainless steel (Chargeability Test), and it was measured to have high electrical Volume Resistivity, which meant that if electrostatically charged, the powder would retain its charge for hours, even when in contact with grounded metal. The powder Minimum Ignition Energy was also measured and found to be 15mJ – putting it in a category of sensitive to ignition by electrostatic spark. But as we have said, in our incident, we are informed, there was apparently a grounding clamp in place to prevent the accumulation of static electricity on the bin.

Trials

It was decided to conduct simulation trials as part of the investigation to really understand the cause of the incident. Sieving trials were designed that replicated the sieving operation at the time of the incident.

In setting up for the trials, it was established that the floor in the sieving bay was an epoxy floor and measured to be electrically insulating. It was also established that the receiving bin had 4 wheels made of nylon – which were also confirmed by measurement to be electrically insulating. This meant there was the possibility of electrostatic charge build-up on the receiving bin in the absence of proper electrical grounding.

The time for trials arrived. Charge generated on the bin was to be measured by connecting the bin’s grounding cable to ground via a nano-ammeter. This is an investigatory technique that permits powder charge generation measurement to be made safely without creating hazardous voltages on the bin. So, with a pre-check on bin grounding and measurement of bin electrical capacitance, the simulation experiment began.

The first sieving trial demonstrated clearly that the streaming current (static charge entering the bin with the powder per second) produced by powder particles becoming charged as they pass through the sieve screen and the chute would quickly generate a voltage on the bin if it were not connected to ground. In fact, with no grounding, the voltage on the bin would skyrocket to a staggering 16 kV within one minute; enough voltage to cause a (15mJ) spark capable of igniting the combustible dust-air mixture inside the bin.

And there was another chance observation during one of the trials. The bin had 4 wheels – two wheels on the left and right sides plus two smaller wheels, one at the front and one at the back. It was noticed that when the bin was roughly half full, it would rock about its side wheels and move the bin forwards by about one centimetre (half an inch) closer to the sieve body during filling.

Taking stock

So, it was convincingly demonstrated that the sieving operation in question does generate substantial static electricity in practice, exactly as predicted by the laboratory testing. We also know that in a scenario in which the bin is not grounded, charge will rapidly build up, and within a minute or so the bin would acquire sufficient charge to generate the 15mJ electrostatic spark required to ignite the dispersed dust. We also know that part way through sieving, the bin could rock towards the grounded sieve body and close a gap in which, given the ad-hoc draped plastic dust sheet, there is likely to be a dense airborne dust cloud.

Everything was in place to explain the incident: a dustier powder and increased dust cloud concentration in the bin (because of the draped plastic sheet), including at the point of a closing (spark) gap. Yet we were told that there was a grounding clamp in place on the bin that clearly should have prevented the accumulation of static electricity on the bin.

Squaring the Circle

All became clear: in subsequent discussion with operators, it was apparent that although the importance of the grounding clamp was understood, it was not necessarily understood that application of the grounding clamp on top of the improvised plastic sheet would not result in the grounding of the bin. To be effective, the clamp needed to be applied directly to the bare metal of the bin. Of course, we also cannot entirely rule out that inadvertently, no grounding clamp was used at all at the time of the incident. Regardless, the use of the ground glamping over an insulating plastic sheet could certainly be problematic, especially where the bin wheels and flooring would provide no alterative conducting path to ground for static electricity.

Findings and Lessons Learned

The flash fire incident and the subsequent investigation led to several crucial findings and invaluable lessons:

Know Your Fuel: Understanding the hazard properties of the materials you are working with is imperative, as underscored by NFPA 652: Standard on the Fundamentals of Combustible Dust. A basic set of dust explosion test data would likely include Minimum Ignition Energy (MIE), Minimum Auto-Ignition Temperature (MAIT-cloud), Maximum Explosion Pressure (Pmax), Explosion Severity Index (Kst), a thermal stability screening test, as well as Electrostatic Chargeability and Volume Resistivity, if static electricity could be an issue. Good combustibility data is always the starting point for any Dust Hazard Analysis (DHA).

Engineered Solutions:

- Appropriately-designed local exhaust ventilation/dust collection is clearly superior to an ad-hoc plastic dust sheet for dust control.

- Conductive plastic/rubber wheels and static dissipative flooring that would provide ‘automatic’ grounding of the bin is markedly more reliable than relying on an operator to remember to apply the grounding clamp. Alternatively, a braided metal strip or chain that is firmly attached to the bin at one end and brushes against a (static dissipative or conductive) floor surface could be used.

Training: It’s important to train operators on dust fire and explosion hazards and safety measures (including static electricity) associated with their work with reference to standards such as NFPA 652 and NFPA 77. The incorrectly applied grounding clamp is a training issue in our incident, as was the improvisation of dust control.

Expert-Led Assessments: It’s clearly important to identify locations where flammable dust atmospheres may occur and to consider and eliminate ALL potential ignition sources that are or could be present under both normal and abnormal conditions. Static electricity is one such source of ignition. In general, it’s essential to identify and employ appropriate explosion prevention and protection measures. This is all part of the DHA, per NFPA 652.

But DHAs must be led by a qualified person, as specified in NFPA 652. And even then, it must be appreciated that some ignition sources, such as electrostatic discharges, can easily evade conventional risk assessment techniques. Sometimes there is a benefit in focused electrostatic hazard assessments which aim to find potential electrostatic problems that might evade conventional hazard and risk assessment techniques. Alternatively, in our view, the involvement of persons in the DHA that understand static electricity and its control is a must.

Written Safety Management Programs: Management of change should always be a feature in well-run process safety management programs. Afterall, CHANGE was made to the process (fine powder, introduction of plastic dust cover) that resulted in dispersed dust at higher concentrations. Management of Change should have required at least a partial reassessment of the process hazards in this case.

In the world of industrial processing, in pharmaceuticals and all other industries, safety should be paramount. Dust combustibility test data and industry standards such as NFPA 77 and NFPA 652, if properly applied by experienced and expert process safety practitioners, can be used to reduce risk and improve process safety. Incidents of the type described here, and their investigation, also add to the knowledge pool and can help all companies improve safety and prevent accidents in the future. Lessons learned, industry standards, and guidelines and adherence to best Hazard Analysis practices guided by experts can save lives and protect operations.

For more information or to discuss how Stonehouse Process Safety can help you assess electrostatic hazards at your facility, please reach out to us at [email protected].

Thanks to the Institute of Chemical Engineering, UK for permission to use some of the source material in this article.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.