How to Comply with NFPA 652, Standard on the Fundamentals of Combustible Dust

NFPA 652 is relevant to most businesses. We explain here what NFPA 652 is all about, why it is relevant to you, and how we can help you achieve compliance with the requirements for your facilities and operations.

What is NFPA 652?

NFPA 652 is a technical standard prepared by the National Fire Protection Association that provides the basic principles and requirements for identifying and managing fire, flash fire, and explosion hazards of combustible dusts and particulate solids. The standard is intended to provide the minimum general requirements necessary to manage the fire, flash fire, and explosion hazards on your facility.

NFPA 652, if properly adopted and implemented, will help you protect the people that work in and around your facility, protect the community, and will secure your production and operating capability for the long-term.

Do I need Combustible Dust Testing?

The standard NFPA 652 applies to all facilities and operations that manufacture, process, blend, convey, repackage, generate, or handle combustible dusts or combustible particulate solids. If you are handling or processing combustible powders it is very likely that NFPA 652 is applicable and that a Dust Hazard Analysis (DHA) is required. Combustible dust testing is important to ensure safety requirements are met.

Understanding dust explosions – Dust explosion testing

Dust cloud flash fires and explosions can occur when the following conditions come together:

- An explosible dust cloud develops.

- There is an oxidant present (this oxidant is usually just air).

- An ignition source occurs (eg flame, hot surface, electrostatic spark, electrical spark, thermal decomposition….) with enough energy to initiate the explosion.

Explosible dust concentrations in air occur with most powder/dust handling operations including powder transfers, in hoppers and silos, mixers, blenders, dryers, sifters, dust collectors/ bag houses, packaging machines and more. They are often present for long periods inside such process plant and can occasionally occur outside of that equipment and even in the workspace. In the presence of an ignition source, a dust explosion or fire hazard will exist. It is essential that effective precautions are taken to identify where dust clouds can exist and then take steps to mitigate this risk by hazard elimination and control measures and by ensuring protection of employees, contractors, the public, the environment, and business. This is why dust explosion testing is so important.

Objectives of NFPA 652

NFPA 652 sets out to provide guidance on how to:

- Protect all people from serious injury from flash fires and explosions, and to protect property.

- Limit consequential damage and ensure that production, and operating capability of the facility is to a level that the owner/operator can accept.

- Protect adjacent and neighborhood buildings, enclosures, facilities, and emergency life safety systems – and the environment.

How Stonehouse can help you with NFPA 652

Our specialist dust fire and explosion consultants can help you practically interpret and apply the requirements of NFPA 652 to your facilities and operation. We can guide you along the whole journey from hazard analysis and assessment through to hazard elimination and risk control, giving you access to our knowledge, expertise, and many years of dust explosion experience to ensure you move to compliance in a safe, cost effective, and efficient way.

At Stonehouse, our process safety specialists can assist with:

- Laboratory Screening Tests: These determine if your powders are combustible or explosible (Go/No-Go tests). We performed these dust/powder tests in our own laboratory. Read more about dust testing services.

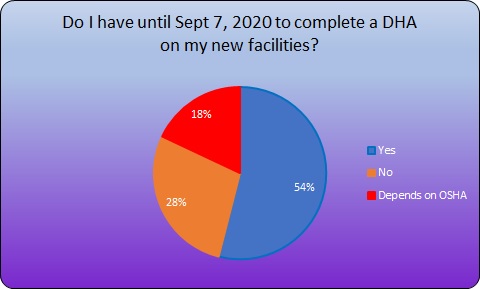

- Conducting the Dust Hazard Analysis (DHA): DHA is a systematic review to identify and evaluate potential dust fire, flash fire, and explosion hazards and is a requirement of NFPA 652. Your DHA must be conducted by someone with proven expertise in hazards associated with handling and processing combustible particulate solids. Read more about Dust Hazard Analysis.

A DHA undertaken by our dust explosion specialists at Stonehouse Process Safety will….

- Provide independent cost-effective advice on avoidance/control of explosible dust clouds, considering such things as dust accumulations, design, operation, and maintenance of local exhaust ventilation in those locations where any dust release is anticipated – and effective housekeeping programs.

- Consider elimination and control of Ignition Sources, considering heat sources, friction and impact sparks, electrical arcs and sparks and electrostatic discharges and more. Such work will include survey work related to electrostatic hazards control, welding cutting (hot work) processes, use of properly rated electrical equipment (Hazardous Location Assessment), consideration of self-heating capability of powders……

- Review existing protection measures against the consequences of an explosion – providing advise on explosion protection systems such as explosion relief venting, explosion suppression, explosion containment, and explosion isolation; all to ensure that if an explosion were to occur at your facility, people are protected, and plant can be returned to production as quickly and easily as possible.

- Review avoidance/control of oxidant by design of inert gas systems, considering Limiting Oxidant Concentration (LOC) values of powders processed.

- Full Laboratory Testing of your Powders: We can obtain all the detailed powder fire and explosion test data you will require per NFPA 652 for the DHA. This includes measuring explosion strength (Kst), minimum ignition energy, maximum safe storage temperature and much more – all in our world-leading dust explosion laboratories. Read more about dust testing services.

- Process Safety Management Programs: We can help you develop the written management systems that are specifically required by NFPA 652 for the on-going management of dust fire, flash fire, explosion hazards. Read more about Process Safety Management programs.

- Training/Competency Building: We can train your operating, engineering, and management staff to validate and assure the levels of understanding and experience exist within your workforce to implement and maintain the necessary on-going requirements of NFPA 652. Read more about process safety training. We also offer virtual process safety training courses such as Exploding dusts, Explosions, Static Electricity and HAC (Hazardous Area Classification). Find out more here.

- On-going Review and Support: And finally, we can review any existing Dust Hazard Analysis (DHA) you may have already performed to check validity and assist in implementing the findings and recommendations. NFPA 652 requires that each DHA must be reviewed and updated at least EVERY 5 YEARS.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.

* indicates required fields