Search

Explainers: What is Kst, Pmax…?

If you have any interest in dust explosions you will have heard of the mystery term ‘Kst’ value. It’s an often-quoted physical property of a combustible dust/powder. It has some rather strange units too – bar.m/s [yes, that’s bar-meters per second]. You will also have encountered the terms ‘Pmax’ [bar] and ‘maximum rate of pressure rise’ [bar/s]. So, what do all these mean and how are they used in dust explosion safety / dust hazard analysis.

Let’s tempt you with some feel-right science….:

Pmax

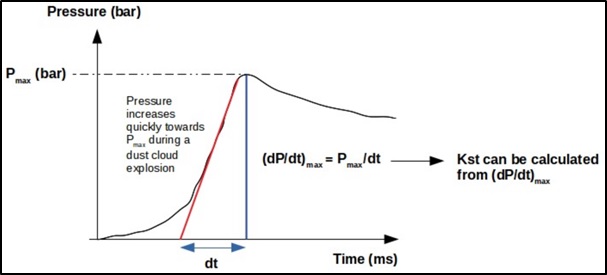

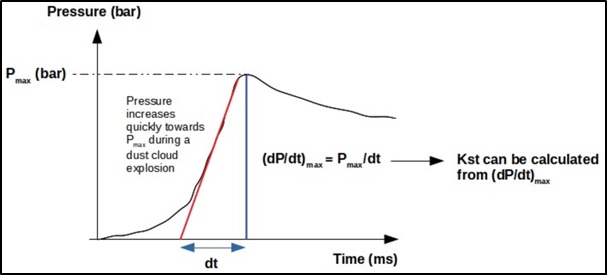

Dust explosions involve the combustion of individual powder particles in the dust cloud that transfer their heat on to adjacent particles and a chain reaction begins. Once an explosion starts, heat is produced which leads to increase in pressure (hot gases expand). If the explosion is inside a closed, strong vessel, the burning will continue until there is insufficient powder (fuel) or air left to burn anymore; it’s been largely used up. So perhaps you can see that an explosion inside a strong, closed vessel will have a pressure profile beginning at atmospheric pressure then rising up to some maximum value – as shown on the diagram. If test conditions are optimized and standardized for concentration, turbulence and more, then this maximum pressure value we term ‘Pmax’. So that’s one of our 3 powder properties defined already!

[Of course, if the explosion happens inside a ‘normal’ process vessel, the vessel will likely rupture catastrophically and Pmax will not be reached!]

It’s important to know that ‘Pmax’ is pretty much independent of vessel size*, so if we measure ‘Pmax’ in our 20-Liter laboratory test chamber at Stonehouse, you could see more or less the same ‘Pmax’ in your dust collector or hopper – provided it is strong enough to withstand the full pressure! ‘Pmax’ is a property of the powder and can be used by a plant designer who wants to design their plant strong enough to withstand the full pressure of an explosion. This is pretty rare, however, since process plant will not withstand anything like the 7 to 10 bar or so pressure that dust explosions typically generate, so we are looking to moderate the explosion so as to permit a reduced explosion pressure, Pred. We do this by installing explosion protection measures like explosion relief vents or explosion suppression. More on that later.

Maximum rate of pressure rise

The maximum rate of explosion pressure (dP/dt max) is another important parameter. As an explosion starts, the combustion initially accelerates as the pressure inside the vessel increases. The rate of pressure rise will reduce later as the explosion starts to run out of fuel or oxygen – so it must therefore have gone through a maximum rate of rise. That’s where the gradient on the example chart is at its steepest. If we want to find the real MAXIMUM rate of pressure rise in our laboratory testing, we need to repeat tests to vary dust concentrations.

If you are going to install explosion relief vents on a vessel, it feels right that the size of these relief vents should be related to the explosion severity, as indicated by the maximum rate of pressure rise – and it is.

Kst

So that’s (dP/dt)max – but unfortunately there is a complication. It turns out that although maximum explosion pressure is fairly independent of vessel size, rate of explosion pressure is not. In fact, the larger the vessel volume, the lower is the maximum rate of pressure rise. This is not to say that Explosions in smaller plant and equipment will be more destructive than those in larger plant. To the contrary, in the latter there is more dust (fuel) and air to cause more damage overall!

Fortunately there is an approximate mathematical relationship between vessel volume and dP/dt max, so if we measure Kst on your powder in our Stonehouse 20-Litre sphere laboratory test chamber, we could work out for you what is likely to be the maximum rate of pressure rise for your plant and equipment. For the keen mathematicians, here is the equation:

Kst = (dP/dt)max x V1/3

From this we can go on to work out for you what size and opening pressure of explosion relieve vents you need to prevent your vessel from rupturing** – to keep the explosion pressure below the Pred, as we say.

In fact, Kst is an internationally agreed ‘normalized’ rate of pressure rise. It is defined as the maximum rate of pressure rise in a 1 cubic meter vessel. It’s as simple as that. Both Pmax and Kst then are seen to be characteristic of the powder (not the test vessel) – which means different powders can be compared with each other with respect to their explosion severity. We even go further by classifying powders into groups, called St classes, as follows:

| Powder Class | Kst value [bar.m/s] | comment |

| St0 | 0 | Does not explode |

| St1 | 1 to 200 | Weak explosion |

| St2 | 201 to 300 | Strong explosion |

| St3 | >300 | Very strong explosion |

The explanation of the units for Kst now becomes clear. It’s a rate of pressure rise multiplied by a length (cube root of volume). (Bar/s) x m – or bar.m/s

Finally for the curious…

Ever wondered what Kst stands for? Actually, it’s all down to the German speakers of this world. K is just a mathematical shorthand for a ‘constant’, but the st? St stand for ‘staub’ – the German word for ‘dust’.

*Finally for the specialist…

You’ll know that the science behind combustible dust explosions is not simple. We know that there are many factors that can influence explosion characteristics of dust. These include the energy of ignition source, dust concentration, dust cloud turbulence level, vessel size and geometry – and that’s before we get on to powder characteristics such as moisture content, particle size distribution and uniformity of mixing. That’s why it is probably best to be sure to measure the actual explosion characteristics of YOUR powder – as well as engaging one of our specialist combustible dust consultants who will be aware of these subtleties and will have designed many explosion protection systems before!

**Full equations for vent sizing calculation can be obtained from NFPA 68

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.