Search

EXPLAINERS: Flammability – Static Electricity in Plastic Liners and Drums

Take a party balloon and rub it against your shirt. Impress your friends by putting the rubbed area of the balloon against the wall. Hey, it sticks!

Static electricity can be great fun. It can also have serious consequences in process safety if it is not properly understood and controlled. Not everyone realizes that insulating materials (plastic containers, plastic powder scoops, insulating linings of pipes, insulating drum liners, spiral reinforces hoses….. party balloons) can not only accumulate and hold electrostatic charge for hours or days, but if they hold enough charge then ‘brush discharges’ can be drawn from the surface. These discharges can have enough energy to ignite most of the common solvent vapors used by the chemical, pharmaceutical and in many other industries where flammable liquids and gases are handled or processed.

In this EXPLAINER piece, we look at electrostatic discharges from insulating surfaces. The phenomenology we describe here is what is behind best practice to control electrostatic hazards in such standards as NFPA 77 ‘Recommended Practice on Static Electricity’ and IEC/TS 60079-32-1 ‘Explosive atmospheres – Part 32-1: Electrostatic hazards’.

Brush discharges:

Think of a sheet of plastic – a plastic bag (flexible, thin) or the wall of a plastic drum (rigid, thicker). They could be made of an insulating material such as high-density polyethylene (HDPE). If you rub them with a cloth, they will almost certainly acquire a net electrostatic charge – just like the balloon. If the ambient humidity is low enough you may even hear a crackling sound as you rub. If you approach the surface with your finger you may even hear the click of a brush discharge. In a dark room, you can sometimes see faint flashes of light.

What you are hearing, feeling, or seeing here is a discharge of static electricity – a type of electrical discharge we call a ‘brush discharge’. The charge has been stripped (or added to) the plastic surface by the rubbing action, with an opposite charge going to the rubbing cloth. Charge deposited on electrically insulating surfaces in this way then sits and waits. If you approach the charged surface with your finger then the electric field from the surface intensifies and with enough charge on the surface and at a small-enough distance, the electric field can reach the breakdown strength of air. Electricity flows from your finger to the surface, ionizing the air as it goes. This is the brush discharge that you see, hear/feel.

Actually, the charge in the brush discharge soon neutralizes the surface adjacent to your finger, but because charge cannot conduct across the plastic surface, it stops; it’s an insulator after all! You end up with a circle of perhaps 10 or 20cm diameter where there is little net charge. However, move your finger across the surface of the plastic and you’ll likely draw a second and third brush discharge.

From this simple description of the physics at play here, we can deduce three things. Firstly, that multiple discharges can occur from plastic surfaces, secondly, that connecting a grounding cable to a plastic is not going to do any good (static charge doesn’t flow across an insulator surface – unless, perhaps the humidity is super high or the surface wet) and thirdly, that these brush discharges are going to be limited in energy (only a small proportion of the charged surface is lost in each discharge).

The million-dollar question: what is the maximum energy that can be released in a brush discharge from a plastic surface?

Answer: about 4mJ

[For your interest, this number is a laboratory determined number and, as far as we know, roughly the same for all insulators, so long as they can hold the maximum level of charge possible without causing air breakdown.]

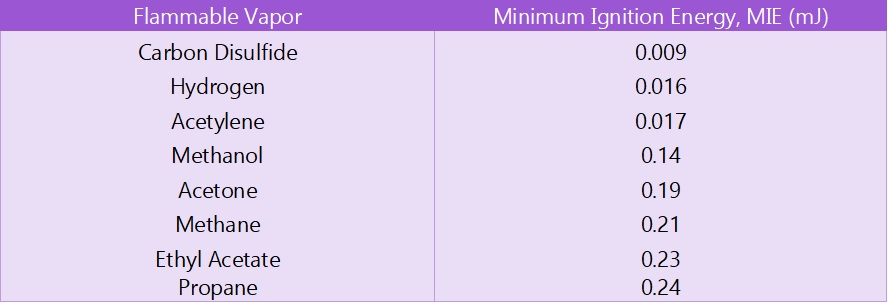

Comparing this maximum brush discharge energy with the minimum ignition energy required to ignite some common flammable solvent vapors, it becomes quickly apparent that brush discharges from plastic surfaces can ignite most flammable solvent/air atmospheres.

Table – Typical Minimum Ignition Energy (MIE) values of some common Solvents

(ref. NFPA 77, 1 Batterymarch Park, Quincy, MA 02169)

Other discharges associated with insulators:

This article is all about electrostatic brush discharges. We have to note, though, that insulating items of plant and equipment can not only produce brush discharges directly, but they can also create insulation barriers that electrically isolate conducting (e.g. metal) items of plant. In this case, spark discharges are produced which can be a lot more energetic than brush discharges. Conducting plant and equipment needs to be electrically bonded and grounded to avoid spark discharge risk.

Use of insulating drums or liners can also lead to build up of charge on powders leading to bulking-brush discharges across the surface of the powder; but this is a story for another time.

If insulating liners are in close proximity to conductors (e.g. a polythene liner in a metal or fiberboard drum) or in case of plastic hoses, or plastic lined metal pipes/hoses, then under a combination of circumstances, propagating brush discharges can be formed – which are extremely energetic with high incendivity to most flammable vapor and explosible dust cloud atmospheres – and potentially injurious to people. Propagating brush discharges do occur in industry. It turns out that the volume resistivity of the lining/liner and its thickness are critical parameters that determine if propagating brush discharges are possible, whether it’s with liquid flow through insulating pipes or hoses or powders bulking in a lined container. This is a complex area and we would welcome any questions you may have about your facility where there are such liner/metal combinations or plastic hoses and pipes.

And finally, we must mention bulk big bags (FIBCs). An insulating type of this bag (type A) can accumulate huge amounts of static electricity as it is filled – enough to generate severe electric shock to the unwary operator that approaches. (ref 1 link) There are other types of FIBC bags made that will provide protection against ignition by static electricity.

For more information regarding flammability and electrostatic discharges, please contact us at 609-455-0001 or email us at [email protected].

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.