Search

Electrostatic Hazards: Early Warning Signs

Electrostatic sparks cause too many industrial fires and explosions every year. Often there are warning signs before-hand. Do you know what to look out for?

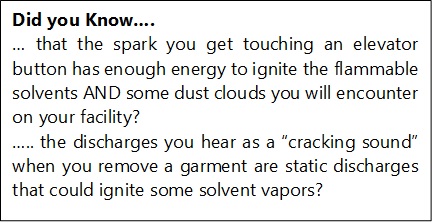

Electrostatics is all-pervasive. We are surrounded by electrostatic effects every day in our lives at home and at play. Ever had a ‘shock’ when you touched an elevator button? Ever heard ‘crackling’ sounds when you brush your hair, removed a garment or stroked a pet? Ever felt a spark from your car as you got out? Surely you have used plastic wrap for keeping food fresh.

With static so prevalent at home, do you really expect it to be absent at work? The main difference, of course, is that in the workplace, things happen at scale and with energy – and we also find extensive flammable atmospheres of low flash-point liquids or combustible powders and explosible dust clouds. An ominous combination.

Our electrostatic hazard consultants spend many hours advising our clients on precautions against static electricity. We even conduct focused electrostatic hazard assessments on plant. But an important observation from our experience is that it is quite usual for ‘electrostatic phenomena’ to be seen at facilities – and sometimes before an incident. Such electrostatic phenomena MUST be reported and investigated with urgency as they can be a precursor to fire or explosion. So here we review the SIGHTS, SOUNDS and EXPERIENCES of static electricity on plant – the early warning signs that need to be investigated.

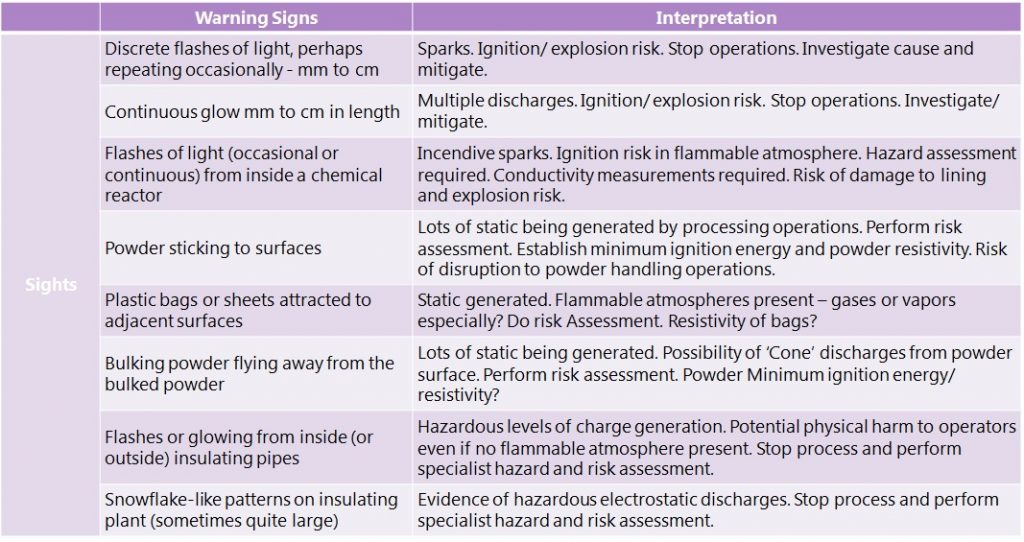

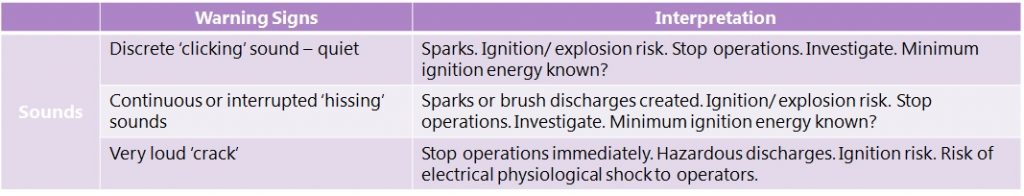

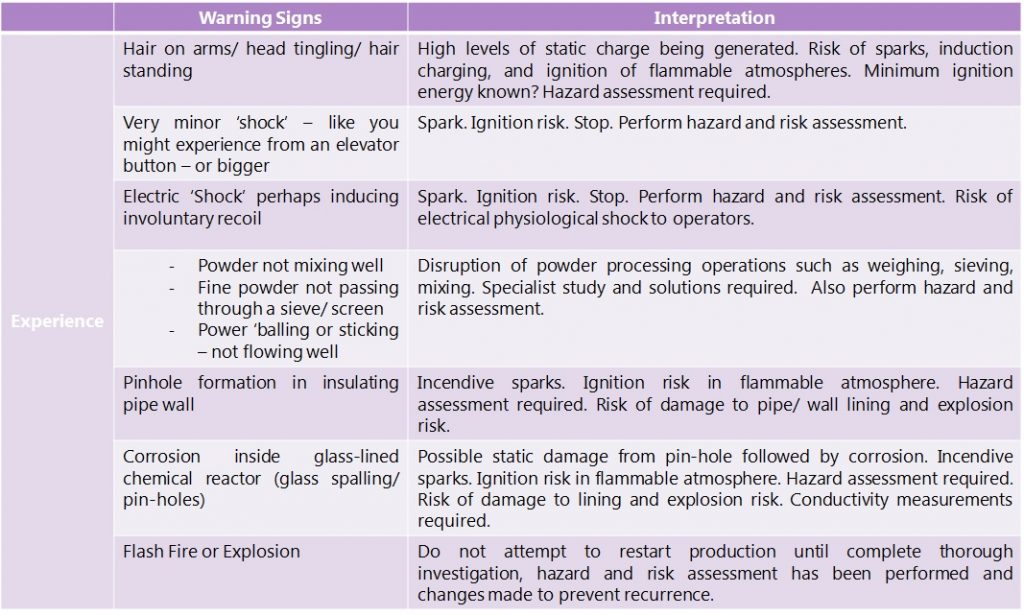

Electrostatic phenomena are there to be found on many an industrial plant – from pharmaceuticals to food processing, agricultural products to plastics and more; you don’t need to look far to see them. Just check out the table below. See anything you recognize? In fact, these phenomena listed in the table can be grouped by ‘class’ – as visible, audible or experiential. Within this classification we observe sub classes as flashes or glows, we hear sounds as clicks, hisses or ‘cracks’ and we experience phenomena such as electric shock, tingling, strange powder flow or adhesion or even damage to plant. So, let’s take a closer look.

Generation

On plant, powder movement and liquid flow can generate huge quantities of static electricity. People also generate static as they go about their work moving equipment, materials or simply walking about; remember the elevator button or shock from your car? Powered machinery and equipment can also generate charge on the equipment or processed materials.

There are things going on here that are common to all. In most cases there is movement with contact and separation of surfaces. Most (but not all) static electricity on plant is generated by so called ‘tribo-electrification’ or ‘flow electrification’ processes – that is the constant making and breaking of surface contact between materials. Powder movement, liquid flow, machinery with moving part and people are ALL subjected to surface contact and separation in some form.

contact + separation = static charge generation

Accumulation

But charge generation is not enough to create the effects described in our table. We do need that generated charge to build up (accumulate) on something if we are to see an effect. Charge can build up on people and plant – fixed or mobile, conducting or insulating. It can also build up on the process materials – usually low conductivity liquids or insulating powders. In fact, charge can accumulate pretty much wherever there is no direct (conducting) path to ground along which the charge may flow.

Accumulation needs a high (electrical) resistance to ground

The effects: early warning signs

Continuous charge build-up is not a stable situation and, in most cases will lead to the breakdown of air which we see or hear as a spark (click/ or crack/ flash), corona or a brush discharge (hiss/ glow).

Sparks: Static builds up on conductors that are not grounded. If there is enough charge, voltage rises and can ‘flash’ to a near-by conductor. Sparks of these types will typically jump a few millimeters. They can be seen from metal drums during filling or emptying, from isolated metal plant such as pipes or conveyors and they are normally discrete events (one at a time). Sparks can also be experienced by operators that have become charged. In all these cases, the sparks are energetic enough to ignite gases, vapors, and dust clouds, and if detected must be investigated immediately.

The use of insulating materials combined with conductors on plant can inadvertently lead to conductors becoming electrically isolated from ground. An example of this being a wire reinforced flexible rubber/plastic hose or pipe such as those used for dust collection or liquid or powder transfer. As powder or liquid passes through the pipe at speed, sparking can occur from the isolated reinforcing wire. Such is the efficiency of this charge generating mechanism that sparks produced this way can sometimes become continuous. Observations of such sparks require immediate mitigating action.

Liquids (usually low conductivity) agitated in a chemical reactor have been known to generate discharges inside the reactor. Glass damage had been discovered (pinholes) which often lead to further glass damage through corrosion. Sparks of this type will only create an ignition hazard if there is a flammable atmosphere present, but no-one wants to witness sparks on their plant, even if under inert gas protection. In any case, re-glassing is expensive!

These types of discharge, which occur when there is a charged insulator in close proximity to a conductor, have their own name – propagating brush discharges They can also occur when powder flows through a plastic hose or pipe, and even when powder collects in a plastic-lined container, hopper or bin. Their energy is huge and is enough to ignite any flammable atmosphere – and cause physical damage to plant and even physiological injury to people. Physical evidence of these discharges includes bright light flashes, noise (crack) and in the aftermath, large ‘snowflake like patterns on the affected insulating surface.

Brush discharges occur from insulators that have become charged. Examples include charged plastic drums, powder surfaces and low conductivity liquids such as toluene or xylene. Brush discharges are limited in energy but can readily ignite common solvent vapors. Brush discharges are not easy to detect, and so measures are taken to control the use of insulators in a production environment.

There is a special case of a brush discharge that can occur across the surface of a powder that is collecting in bulk. Generally, the powder is bulking in a relatively conducting hopper or silo of metal or concrete. The discharges created tend to be radial in direction and multiple in frequency. These discharges are known as bulking brush discharges or cone discharges and have sufficient energy to ignite the more sensitive dust clouds and flammable vapors. It is unlikely that these discharges will be readily observed by eye or heard, although charged powder mysteriously sticking to surfaces is indicative of high charging levels and the possibility of cone discharges should be reviewed.

Powder handling problems: Poor flow, sieving problems or clumping of powders can cause production difficulties but such effects are clear indicators of the generation and accumulation of static electricity. You may also see powder flying away from a bulking powder (e.g. in drum filling) or see the powder sticking as a fine layer to its container walls. If the powder is charged, so is your plant – somewhere. A sign to look further and assess the hazards.

In conclusion:

Static electricity continues to cause fires and explosions in industry. Specialist electrostatic hazard assessments are possible which aim to identify static hazards and methods of control. Such hazard assessment work is the best way to prevent fires and explosions caused by static electricity on your facility. However, evidence of electrostatic charge build-up can present itself to the observant. Sparks and discharges can sometimes be seen, felt or heard, powder can behave in unexpected ways and even an operator can ‘feel’ the presence of static electricity.

Electrostatic effects on plant should always be reported and investigations made to ensure they do not become a precursor to a fire or explosion to follow.

Electrostatic Hazards – The Early Warning Signs

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.