Search

Dust combustibility – why accurate results matter

You know you need to check out your powders for their combustibility. Maybe you need to comply with NFPA 652 (Standard on the Fundamentals of Combustible dusts) – or perhaps your DHA (Dust Hazards Analysis) is missing a Kst value here or minimum ignition energy (MIE) value there. So, you go on-line and find the cheapest lab that can test your powders, right?

Think again.

You must be able to rely on your dust combustibility test data. Decisions you take on explosion prevention and protection measures will use that data and getting it wrong can put lives at risk. But relying on wrong data can also mean you over-do the prevention and protection measures, increasing costs. So, if you are going to go to all that process and expense of obtaining combustibility data on your powders, it really does need to be accurate.

Think again.

When getting it wrong really does matter

Milk Powder: A company had data on its milk powder that indicated a tendency to self-heat at 165°C. The company dried the powder in a spray dryer at a lower temperature. So no problem there then….. or was there? For some batches, small black speckles of powder were being discovered in the final product. Quality Control was not happy about that, of course, but the process safety engineers were even less happy. Black specks suggest decomposition with risk of combustion and even explosion!

A detailed lab study of the product revealed the real exotherm onset temperature to be 20°C lower that the previously measured value. In addition, thicker powder deposits could be shown in the lab to have even lower self-heating onset temperatures.

All-in-all, wrong lab data, improperly interpreted, introducing a real dust fire and explosion risk to the facility.

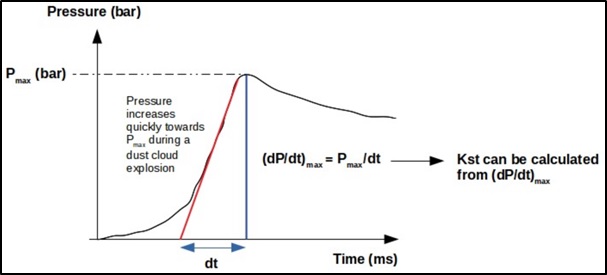

Agrochemical powder: The company had a DHA undertaken by an outside contractor. Explosion relief vent areas of dust collectors were evaluated using explosion severity (Kst & Pmax) data from the company files. The lab that had measured the product’s Kst and Pmax could not be traced! It was reasonably determined that explosion relief ducts were required to be fitted to the explosion relief panels on the dust collectors to direct any dust explosion/combustion products outside the building and to a safe place. The only problem was that using the supplied Kst and Pmax values, it was impossible to design a practical explosion relief system capable of handling the high forces that would be generated by a dust explosion inside the dust collectors. Cue a major engineering upgrade and associated plant down-time and costs? No: Fortunately, someone thought to have the data checked by an independent test lab. The Kst and Pmax were found to be substantially less than those previous results indicated. A recalculation meant that installation of explosion relief duct onto the existing explosion panels could, after all, be designed safely.

In our view the first step in selection of a dust explosion test lab is to find one that operates to an internationally accepted quality standard. For laboratories in our field, there is a specific standard, ISO/IEC 17025:2017, that is of particular relevance. This is the standard that we have chosen to adopt at Stonehouse since it is specifically designed for organizations that perform testing, sampling, and calibration and that demand reliable results. It is a standard that is used by organizations that are owned and operated by government and industry, by research centres, and by certification bodies. It is the standard against which we are independently checked every year; and it is what allows us to provide you with test results on which you can depend.

The ‘International Organization for Standardization’ developed ISO/IEC 17025:2017 some years ago. ISO/IEC 17025:2017 covers standard testing as well as nonstandard testing and novel methods, so it covers pretty much everything a combustibility testing lab will want to do.

So, if you are going to go to the process of obtaining combustibility data on your powders, it really does need to be accurate and reliable. Make sure you chose an ISO/IEC 17025:2017 lab to perform that work for you.

Can we help you with your combustibility testing?

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.