Why perform a PHA?

Pretty much every industrial processing facility will have associated hazards that require attention to ‘Process Safety’. These hazards include explosion or fire, and toxic or environmentally damaging release. Such hazards have the capacity to impact the safety of staff and the general public, to damage facilities, disrupt operations, damage the environment, cause reputational damage and even pose a threat to the continuity of the business.

Although Process Hazard Analysis (PHA) is undertaken by many companies around the world, sometimes it is mandated by national legislation or at the very least encouraged by professional organizations to conduct a preliminary hazard analysis. In the USA, Process Safety Management program OSHA 29 CFR 1910.119 (e) requires PHAs and in Europe it’s the SEVESO Directive. Active professional bodies working to encourage best practice in this field include the Centre for Chemical Process Safety (USA) and the European Process Safety Centre (Europe).

What is a Process Hazard Analysis (PHA)?

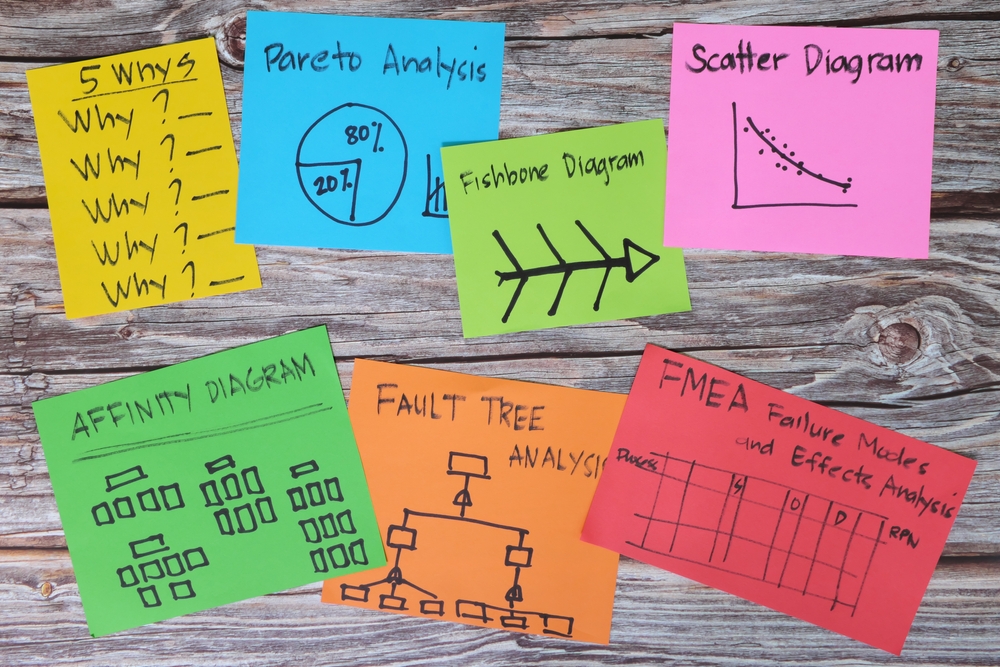

A Process Hazard Analysis (PHA) is a technique used in the process industries to understand what can go wrong in a process, to assess how likely it is to go wrong, and then to establish the precautions required to prevent or help mitigate the consequences of the failure. There are a number of techniques that have been developed by process safety practitioners to assist in this process which when brought together with process safety expertise and knowledge of plant operations can produce valuable studies and ultimately a real reduction in operating risks. These techniques include:

- HAZOP (Hazard and Operability Study)

- What-If

- MHA (Major Hazard Analysis)

- FMEA (Failure Mode and Effects Analysis)

- Fault Tree Analysis

In general, standards and industrial guidelines require or suggest that Process Hazard Assessments (PHAs) are performed for the design stage, operating stage and indeed for shut down. They should also be performed – or at least reviewed – whenever there is a significant change made to the process or operations. Furthermore, it is advised or mandated that a Process Hazard Analysis is validated again every 5 years.

Process Hazard Analysis (PHA) is best performed by a small team of persons assembled specifically for the project in hand. The PHA consultant team will likely include persons who are familiar with the process as well as persons familiar with the hazards. At Stonehouse we are often asked to lead these PHAs but we are equally at home bringing our specialist knowledge in process safety to the team as participants with process safety-related subject matter expertise. We are always happy to discuss the make-up of any specific PHA team that is to be assembled.

Why work with Stonehouse for your Process Hazard Analysis (PHA)?

Stonehouse Process Safety has conducted process hazard analysis (PHA) studies in many industrial sectors including pharmaceutical, chemical, food, metal, and more. These have been performed for multi-national companies and medium/ small operators alike. Our specialists have undertaken PHAs and revalidations and we’ve reviewed existing PHAs for our clients. We’ve also trained the staff of operating companies in PHA facilitation techniques.

Get in touch

Whether you are looking to get an expert to conduct a HAZOP analysis study, fault tree analyses, or what-if study, our process safety specialists are here to help. Stonehouse understands that the quality of a PHA study is dependent on the knowledge, expertise, and experience of the individuals leading and participating in the PHA study. That’s why we work arduously to ensure study quality.

* indicates required fields