Search

Combustible Dust: Sampling for Dust Combustibility Testing

Our ‘Go To’ guide for selecting/collecting your powder samples for combustibility testing.

OK, so you have understood from NFPA 652 that you are responsible for determining if your materials are combustible or explosible, and if so, for characterizing their properties as required to support your Dust Hazards Analysis (DHA) [Ref 1]. Maybe you have selected the tests you think you need, and perhaps even sent an order to a test house somewhere. All you need to do now is collect the samples and ship them, right?

Stop right there.

Let’s take a step back and consider how you arrived at your decision to select those powder/dust samples and then review how you might go about collecting and shipping samples so as to ensure you get test results that can actually be used in your DHA.

Basics

Firstly, please understand that powder combustibility/ explosibility is not like gas/ vapor flammability. The chemical make-up of the material is clearly important in both cases but with powders, fire and explosion characteristics are influenced substantially by physical form, moisture content, and more. The nature of the problem is best illustrated with an example.

We learn a lot from this narrative. We learn that particle size influences dust cloud ignition; we also learn moisture content affects ignitability. We can also surmise that strength of explosion and ease of ignition may therefore be affected by moisture content and particle size – and actually they are. Now you are perhaps beginning to understand why powder sampling for dust combustibility testing is very important. Chemical composition matters, but with any given material, the combustibility properties are affected substantially by other factors that includes moisture content and particle size, shape…. and that’s before we even get on to turbulence and power of ignition source.

Selecting the proper combustible dust: What are we trying to achieve?

In selecting a dust sample for testing we are ideally looking for a sample that is representative of the actual dust cloud that will be present during normal (and abnormal) plant operation. If we are interested in explosion prevention and protection of a dust collector then we can obtain powder samples from the dust collector – may be from the internal bags or ledges. If your DHA is examining explosion risk in the workspace itself, then we may be looking for samples of fugitive dust on equipment or ledges. [Note the DHA will likely be examining ways of preventing fugitive dust emission and accumulation, but real plant is not always perfect and spotlessly clean all the time!] Perhaps we are concerned about the explosion protection of a hopper or silo. In that case we might use a sample from a downstream dust collector, or we may instead decide to collect dust that has built up on the upper internal walls of the hopper. We can be sure that this is the dust that was once airborne in there.

Dust Sampling and shipping Strategy

It is important to have a clear dust sampling strategy and to document this to assist with repeatability and validation of your approach. The sampling strategy would likely include:

- Identification of locations where fine particulates and dust are present,

- Identification of representative samples,

- Collection of representative samples: We would suggest collecting around 1Kg of dust for each material depending on the range of tests to be undertaken,

- The sample integrity must be preserved; suitable sealed packaging, perhaps?

- Communication with the test laboratory regarding sample handling – and specials precautions needed to preserve sample integrity during testing,

- Documentation of samples: samples should be uniquely identified using identifiers such as lot, origin, composition (pure, mixture), process, age, location, and date collected. A safety data sheet will also likely be requested by the test laboratory,

- Safe sample collection practices: Sampling must be done in a safe manner, of course, without introducing an ignition source, dispersion of the dust or increasing risk of injury to operators,

- Materials should be shipped according to DOT Hazardous Materials regulations and should contain the necessary hazard/ warning labels, although this may not always be necessary for small sample volumes,

Dust Drying and Sieving?

If you are operating in USA it will likely be that the test standards used by your chosen dust explosion laboratory will be ASTM standards. Different standards have different things to say about sample treatment but testing dust samples sub 200 mesh (75micron) is common, as is sample drying before testing. Testing fine, dry dust provides a good level of reassurance for material in different parts of plant. Remember that the finest, driest dusts will ignite and explode with greatest ease and greatest explosion forces.

Note on applicable standards and on testing mixtures of powders

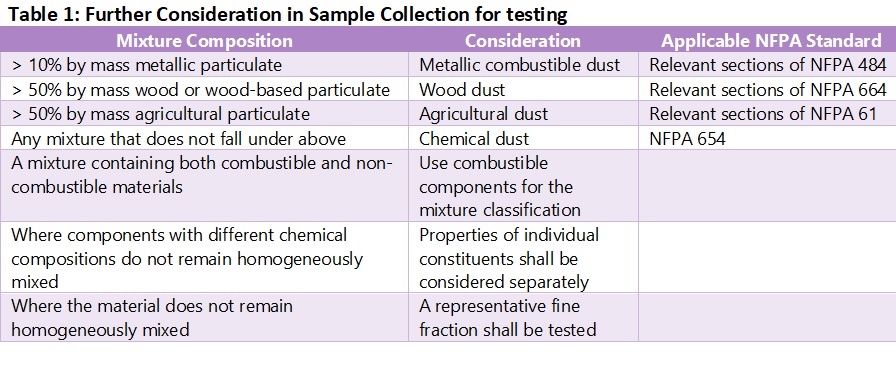

It’s worth noting that there are other standards applicable to dust explosion prevention and protection and in particular there are industry or commodity specific standards that may take precedence over NFPA 652. What’s more, there is the seemingly intractable problem of what to test if you have mixtures of powders. We have included table 1 below that may help address questions that might arise for these different situations, but we would advise a discussion with your test house to make sure you get it right.

Talk to your Safety Testing Laboratory

At Stonehouse Process Safety one of the most important things to us is speaking with our clients about their testing needs. This discussion will generally begin with a description of the process/ plant that is to be assessed, it will allow for discussion on where to select representative samples as well as advising on selection of the most relevant tests. It can also include discussions on sampling techniques, packaging, and shipping where necessary.

We understand at Stonehouse how sample and test selection have a critical part to play in plant safety assessments and in undertaking your DHA for NFPA 652. Our specialist consultants can, of course, undertake your required DHA on your behalf, but we are equally happy just to perform dust explosibility and combustibility testing and to ensure you have the right data that meets your needs.

If you would like to discuss any aspect of dust hazard analysis, or dust combustibility/ flammability testing, please contact us on 609-455-0001 or drop us an email to [email protected].

Ref 1: NFPA 652, Standard on the Fundamentals of Combustible Dust

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.