Search

Grain and Processing Explosions – Why so many?

There are too many combustible grain dust explosions every year in the US; these result in over 30 injuries or fatalities and millions of dollars of loss (ref. 1). There are 2 industrial sectors that stand out as suffering the most explosions – also with accompanying injury, fatalities and damage to plant and equipment. These 2 sectors are Grain/Food processing and Wood Products. These sectors account for over 40% of reported combustible dust explosions in the US each year.

In this issue of Process Safety Dispatch, we focus on the Grain and processing industries, and look inside the industry statistics to try to discover what is going on in this hugely important sector of the US economy. If you are interested in wood dust explosions and fires, you may like to read our web article (ref. 2).

Agricultural dust explosions: Let’s start with some hard data:

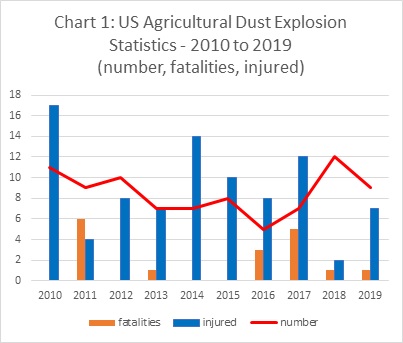

The chart shows the latest data on US Agricultural dust explosions covering the 10-year period from 2010 to 2019 (data source: ref. 3). On the chart we see number of combustible dust explosions recorded each year (c 9 or 10), along with the number of people injured and killed in these explosions. We have to conclude that the number of dust explosions each year shows no evidence of decreasing. We also may conclude that the number of injuries each year is pretty flat. The number of fatalities is also not showing a direction of travel, other than to note that there is something of a cluster of fatalities in the last 4 years.

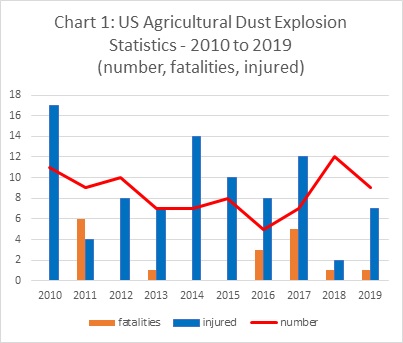

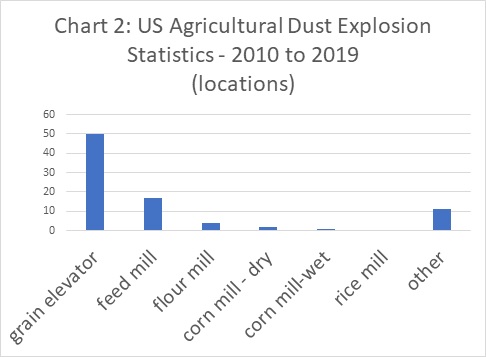

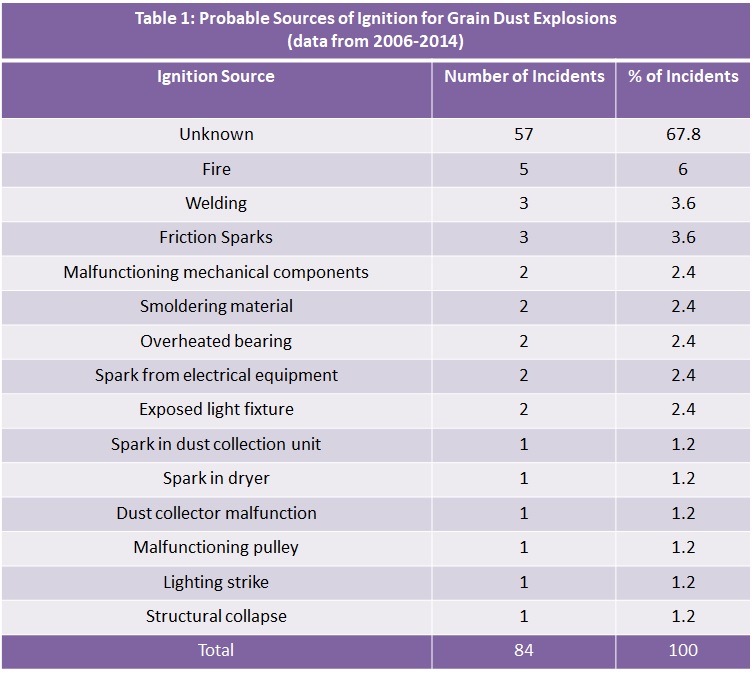

To explore the story behind these numbers we look in more detail at the data. Chart 2 below shows the aggregated data for location of the explosion over the same 10-year period. Table 1 shows the reported sources of ignition from 10 years of explosion data. [The tabulated data is for an overlapping but different time period but is nevertheless revealing]

In drilling down into the data in Chart 1 we are seeing that in the agricultural sector, elevators and mills are the main sites for dust explosions. This is not too surprising:

- Elevators will frequently contain dust clouds when grain is transported, and the moving parts of the elevator have the potential to produce heat (e.g. overheated bearings or heating through frictional contact) or impact sparks. Elevators also will contain electrical equipment that can get hot or even produce electrical sparks if not properly specified and maintained.

- Mills similarly will contain a dust cloud, moving parts and electrical equipment and are similarly prone to ignition. Foreign objects in a mill can sometimes lead to sparking in the mill.

- There are Lots of elevators and mills in use!

What has caused the combustible dust explosion (ignition sources)?

The data in Table 1 shows probable sources of ignition for 84 reported agricultural dust explosions. For the process safety specialist this data is deeply troubling; for 57 of these explosions the ignition source is recorded as ‘unknown’. There are always learnings from properly investigated explosions; learnings for the site and possibly for the wider community. Stonehouse Process Safety is often called upon to investigate explosions, their causes – and to make recommendations for future safe operation. We strongly believe that extensive efforts should be made to establish cause (or likely probable causes) of industrial incidents before rebuild/ modifications are specified. These efforts should best involve a dust explosion expert. They would also involve obtaining laboratory test data on the powder(s) to establish minimum ignition energy, minimum ignition temperatures and explosion severity data (Kst and maximum explosion pressure). These data can be used to exclude (or include) ignition sources such as static electricity, electrical ignition, impact/ friction ignition and product self-heating from the investigation. The Kst value will be used to ensure rebuilt plant can safety cope with an explosion in the future, should one occur.

So, what can be done to reduce the number of agricultural dust explosions in the US?

First off, if there is no dust cloud there can be no dust explosion. As I write this, I can hear the industry old-hand saying that wherever there is grain there will always be dust. Of course, this is true but there is no doubt that dust extraction and effective housekeeping will minimize airborne dust in process plant. It is for sure that cleaning – removing settled dust will help. If there is only a little airborne dust (below the minimum explosible concentration) then starting a dust explosion will be difficult. Removal of settled dust will help minimize and even prevent the dreaded secondary dust explosion, where settled dust is raised by the pressure wave of a primary dust explosion, only to be ignited by the pursuing flame front.

There are other important measures too. These include regular maintenance of equipment, judicious use of vibration monitors, automatic plant shutdown on fault conditions, magnetic separators to remove foreign objects and more. Of course, explosion relief venting is available for process plant such as elevators. The installation of explosion relief venting will not prevent a dust explosion from starting but if carefully designed and properly sited will ensure the plant does not disintegrate should an explosion occur. Explosion relief vents need to be designed to discharge to a safe area to protect people.

We must also consider the education of staff. Employees and contractors alike can clearly be a source of explosion as the statistics demonstrate. Welding operations should not be allowed to feature at number 2 of known ignition sources in table 1. Staff should not only be trained to avoid causing dust fires and explosions, but they are also the first line eyes and ears of good process safety management – who can look out for and report anything unusual or troubling. Timely reporting of a dust escape or an unusual sound from plant will save lives and livelihoods.

Finally, we turn to management and control systems (e.g. hot work permits, inspections, walk-arounds….). These have to be up to standard to ensure there are proper procedures and checks so that the plant is run in a well-defined and safe way.

If you would like more information on our independent advice services in dust explosion prevention and protection, please contact our dust explosion specialists on 609-455-0001 or [email protected].

References

- Chemical Safety Board: https://www.csb.gov

- Stonehouse Process Safety Dispatch article https://stonehousesafety.com/ss-case-studies/sawdust-explosion/

- Data obtained from Purdue University: https://engineering.purdue.edu/Engr

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.