Search

Dust Quiz; The Results! How much is known about NFPA 652

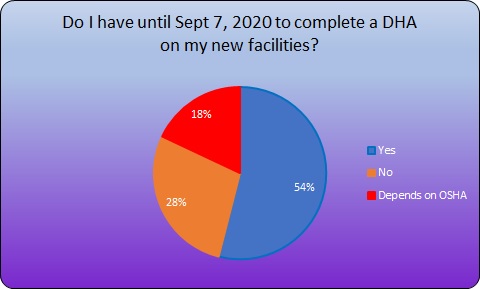

A couple of months ago we gave you, and colleagues like you, the opportunity to take a (hopefully fun) quiz to find out what is known in the process Industries of North America about NFPA 652 – Standard on the Fundamentals of Combustible Dusts. We looked to discover how much is known about company obligations and responses, about who should do what – and about what to do after the Dust Hazard Analysis (DHA). Afterall, there are only 9 months to go before the requirement to have completed a Dust Hazard Analysis (DHA) on existing processes comes into effect (7th September 2020).

For the interest of all readers of our Process Safety Dispatch, here are the results.

[But by the way, if you still would like to test your knowledge, we’re keeping the quiz live for a little longer. Follow this link if you would like to take the dust quiz yourself now. All answers are confidential to you alone. [Stonehouse staff only see aggregated results.]

The Results

So here we go……

First off, over 150 people volunteered to take the quiz. Thank you. There were 10 questions to test your knowledge and the first result is….

Respondents got 2 out of three questions correct, on average; not too bad an outcome perhaps. But there were a number of important areas that show a definite misunderstanding of the requirements and obligations of NFPA 652. We look in turn at some of these…

We began the quiz with a seemingly simple (yet slightly devious) first question.

‘I’m processing a very dusty powder. Do I have to perform a Dust Hazard Analysis (DHA) in accordance with NFPA 652?’ Most people answered a clear ‘Yes”. Only 30% of respondents spotted that you needed more information to answer this question properly! May be this question was a little unfair to begin, but there are a number of important exemptions and situations where NFPA 652 does not apply. If the powder is not combustible, for example, then NFPA does not apply. Simple screening tests are available at Stonehouse (combustible dust tests) to establish if a powder is combustible. There are other exemptions too and these are detailed in the responses seen by those who took the quiz.

Fortunately, most respondents understood that NFPA 652 does not apply at home in the kitchen. There were 9 respondents who did feel they needed a Dust Hazard Analysis (DHA) at home (or maybe hit the wrong button!) Of course, flour and confectioners’ sugar, for example, can ignite in the kitchen too; it’s just that it’s not covered by NFPA 652.

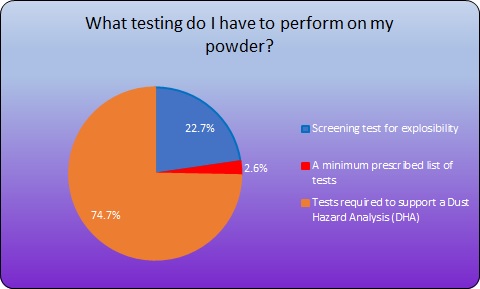

‘What testing do I have to perform on my powder?’ Most people (75%) realized that combustibility testing may be required to support the Dust Hazard Analysis, (DHA). Contrary to some belief, there are no specific tests demanded. Lab investigation can range from a simple screening test for simple processes through to a comprehensive set of tests that investigate properties as diverse a sensitivity to electrostatic sparks or hot surface ‘auto-ignition’ – through to thermal stability testing. Determination of Kst and explosion pressure will likely be needed if explosion protection measures are employed such as explosion relief venting or explosion suppression. About half of respondents also realised that they MAY be able to use dust test data obtained from a public source such as the internet – BUT the public data MUST be for a dust that is identical in all key respects to the dust processed on their plant. Particle size, moisture content… are just two of those properties that must match.

At Stonehouse we like to discuss sample collection and laboratory test selection for Dust Hazard Analysis (DHA) purposes with our clients. We have provided more information on tests and their uses at this link

And on a similar topic, in answer to the question ‘Who is responsible for determining the explosibility hazard properties of the powder I process at the facility?’ 44% of respondents did not realize that it was the responsibility of the owner/ operator of the facility to obtain this test data. 39% of respondents believe the material supplier had at some responsibility here.

We did ask if you needed to bring in an external expert to conduct the Dust Hazard Analysis (DHA) on your behalf. 83% of respondents correctly identified that you could do the Dust Hazard Analysis (DHA) in-house – but only if the assessor was sufficiently experienced/ qualified.

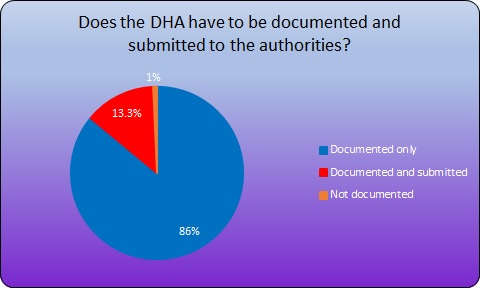

Our final questions related to what to do once you had your Dust Hazard Analysis (DHA). Whilst 13% of respondents believed they had to submit their DHA to the authorities (incorrect), in answer to the question, ‘I engaged a process safety consultant to perform a Dust Hazard Analysis (DHA) for my facility. Am I finished now?’ a third of respondents believed they had finished. In fact, the Dust Hazard Analysis (DHA) is really just a steppingstone towards the operation of a safe facility. NFPA 652 requires the hazards identified during the Dust Hazard Analysis (DHA) to be addressed by developing an action plan to manage the necessary changes to process materials, physical process, process operations or facilities. In addition, written safety Managements Systems would be needed to ensure continued safety of the operators, facility, and the community. This could involve things such as:

- written procedures for operating the facility and equipment to prevent or mitigate fires, deflagrations and explosions

- training programs according to the potential exposure to combustible dust hazards and the potential risks

- The establishment of safe work practices to address hazards associated with maintenance and servicing operations – and their application to employees and contractors.

- A periodic walk-through review of operating areas and a schedule established to verify that operating procedures and safe work practices are being followed.

If you would like to discuss anything related to the application of NFPA 652 to your facility, please give us a call for a complimentary discussion.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.