Search

Self-Heating Hazards of Powders

“In simple terms, when the rate of heat generation exceeds the rate of heat loss, temperatures can rise and accelerate fast. If left unchecked, this can result in smoldering, fire and sometimes explosion.“

By Vahid Ebadat, Ph.D., Stonehouse Process Safety, Inc.

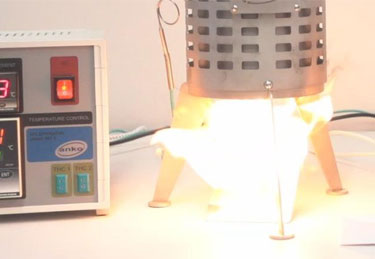

When powders are heated, subtle sources of ignition can present themselves that are associated with the heating process – and perhaps the inherent instability of the powder being heated. Self-heating occurs when the powder temperature is raised to a level at which the rate of heat liberated by the exothermic reaction exceeds the rate of heat lost to surroundings. This can result in a runaway increase in temperature and subsequent smoldering, fire, and/or production of hot or incandescent particles, which can travel along conveying equipment and act as an ignition source to dust clouds downstream. Time can also be a factor since some exothermic reactions take a while to get established.

Industrial operations, which are prone to fires and possibly explosions due to self-heating, include powder drying/heating and its subsequent processing, handling, packaging, storage, and transportation. Typically, powder drying operations involve the application of heat to a solution, wet powder, or slurry. Bulking and packaging of the dried powder usually follows. Common dryer types include tray, fluidized bed, spray, rotary, and vacuum dryers. In any type of dryer, the dry powder can build up as a bulk or layer in various locations within the dryer, in downstream process equipment, or, ultimately, in hoppers, silos, big bags, or smaller packages.

Preventing self-heating and subsequent fires and explosions in any operation or situation where the powder is subjected to heat requires proper understanding of the thermal instability properties of the powder through specific and tailored laboratory tests. However, for laboratory testing to provide a usable indication of the hazards, the test sample must be representative of the powder in the process, and the laboratory tests must also reasonably simulate the conditions experienced by the powder during the drying and subsequent downstream storage, packaging, and transportation stages of processing.

Precautions for avoiding smoldering, fires and explosions include:

- Keeping the powder temperature at a safe margin below the temperature for the onset for self-heating, obtained by appropriate test methods

- Designing the facility and equipment to avoid ledges, corners, dead zones etc., where powder could inadvertently build up inside process equipment

- Avoiding accumulation of hazardous levels of powder deposits on the inside surfaces of process equipment

Vahid Ebadat, Ph.D., M.Inst.P, MIET C.Phys., is CEO of Stonehouse Process Safety Inc. He has worked extensively as a process and operational hazards consultant for the chemical, pharmaceutical, food, oil and gas, and paper and wood industries. Ebadat has published many technical articles and papers globally and speaks widely on the topics of process safety, dust explosion mitigation, gas and vapor flammability and controlling electrostatic hazards. For more information, call 609-455-0001 or email [email protected].

Stonehouse Process Safety, Inc.

Get in touch

To learn more about our expertise and services in dust explosion prevention & mitigation, call us at +1 609 455 0001 or email us at [email protected] today.

We also offer tailored virtual and in-company process safety training programs on Dust Explosions, Static Electricity and HAC (Hazardous Area Classification) and more. Find further information here.

We use cookies to help us enhance your experience on our website. By clicking “Accept,” you consent to our use of cookies. Read our Privacy Policy for more.