Hierarchy of Controls in Process Safety

Process Safety is all about protecting people, plant, the environment, and your business from the consequence of ‘loss of containment’. We are always careful in our process hazard analysis work at Stonehouse to establish why a particular operation can be considered to be safe. If it is not, then we determine what changes are needed to achieve an acceptable level of safety. We term this process ‘establishing a ‘Basis of Safety’’.

So, let’s consider why a particular industrial process can be considered to be safe…

Perhaps it helps to have an example in mind as we work through the steps, so let’s think of an actual process. Let’s keep it really simple and think of the humble powder storage bin – metal, closed at the base and slowly filled with a combustible powder from the top under gravity.

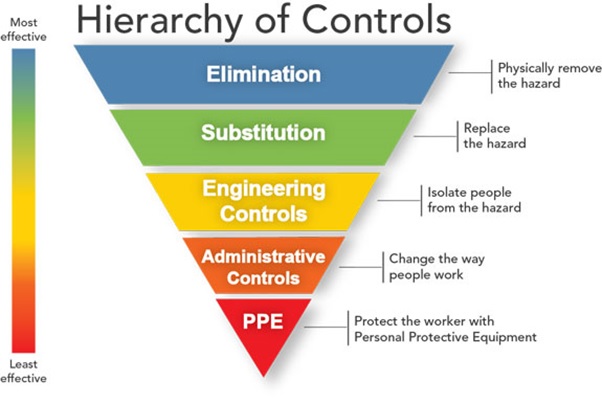

The hierarchy of control as applied to process safety has 5 elements which are to be considered in turn, beginning with the most effective.

Elimination: If we are filling our bin with a dusty powder, we will likely create an explosible dust cloud during filling. If the powder is solvent wet there may also be a flammable vapor atmosphere inside the bin too – creating a hybrid mixture. Elimination here means asking ‘can we eliminate the flammable dust and vapor atmosphere’? Maybe we can use non-dusty pellets rather than powder. Perhaps the powder does not need to be solvent wet at this point.

Dust extraction systems clearly have a role to play here as does good housekeeping processes. It’s a moot point in many situations as to whether a particular dust extraction system has reduced the flammable atmosphere to below its flammable limit (minimum explosible concentration) but what’s for sure is that simply reducing the extent of any flammable atmosphere and preventing dust escape to the work place is invaluable and will certainly reduce likelihood of explosion and reduce destructive effects, should one occur. It is also evident that housekeeping to remove escaped dust is also essential to prevent secondary (and primary) explosions in the workspace.

Elimination of the flammable atmosphere is clearly a great move if you can do it, but it can present practical challenges. Even so, good investigative thinking will always challenge this point with the plant technical and operating staff, since improvements here can bring significant risk reduction.

Substitution: So, the powder going into our bin has to be solvent wet, but why does it need to be wet with a particularly hazardous solvent such a toluene, say? Could the solvent be substituted for one that is ideally not flammable at all? Or even we can ask if the powder going into the bin has to be so fine. Is it possible to substitute with a powder with larger particle size or which is less dusty? Measurement of minimum ignition energy and minimum explosible concentration of the dust will guide us here as to whether a substitute powder is indeed harder or easier to ignite than the original.

If we really have an ignition risk in a particular operation, can we even consider substituting air in the system with a reduced oxygen atmosphere, where some of the air is replaced with nitrogen? Flammable atmospheres partly depleted in oxygen could be incapable of supporting fire and explosion but even if not totally inert will be more difficult to ignite (more energy required for ignition) and the severity of the explosion would be reduced.

Engineering controls: It is interesting to note that when something goes wrong in a facility and an explosion happens, investigations often focus on engineering controls and their absence or failure. Engineering controls could include things like oxygen monitors (if inert gas is used) or perhaps ‘spark’ detection/ quenching systems. For larger bins they may include explosion relief vents, or explosion suppression, and isolation systems. Electrically bonding and grounding of metal process plant is essential to prevent electrostatic spark formation, but this is not always enough. Electrostatic discharges can occur from insulating components in conveying systems and even from the surface of the powder itself if it is insulating. Measurement of minimum ignition energy of the powder and its Volume Resistivity and Electrostatic Chargeability will provide insight into the most appropriate engineering explosion prevention measures here. Explosion protection measures such as explosion relief venting will require measurement of Kst and Pmax values of the powder/ dust.

Another engineering control method is separation. Here the operators are separated from the potentially hazardous plant. In the case of explosion relief venting on plant and equipment it is still surprisingly common to find dust collectors in the middle of a factory. These dust collectors are expected to have explosion protection, but if the explosion vents are designed to discharge into a space where operators work, there is clearly a problem. Engineering design will be at its best when such vents have duct work that discharge the explosion product (hot gases, flame, and forces) to a safe place, normally outside the building. Or perhaps better to install the dust collector in a safe outdoor location in the first place.

Administrative controls are clearly important in maintenance of process safety precautions that guard against fire and explosion on plant. Good process safety management systems are required that ensure proper information is available, that process hazard analyses (PHAs) are properly completed, that operator training schemes are in place….. and a whole bunch of other things including, managing contractors, hot work systems and checks that what is supposed to happen (operating procedures) are being followed. In our simple example, it would be devastating if a welding operation were allowed to take place on a vessel containing the residue of a combustible powder, a dust cloud, or flammable solvent vapor.

Finally, to PPE. Most people would agree that PPE is the last line of defense in any occupational health or indeed any process safety scenario. Exposure to risk that relies solely on PPE should be designed out of any operation. In a process safety context, it is difficult to imagine where one would rely on PPE to protect an operator from the force of an explosion! That does not mean that flameproof work wear is not important as are safety footwear, goggles, gloves, respirator, hats, …. but it does mean that we are not going to try to design a basis of safety that anticipates an operator being caught in a fire or explosion.

In summary, the principles of ‘Hierarchy of Control’ as laid out by NIOSH [ref 1] can be applied to process safety. Process Safety is all about protecting people, plant, the environment, and your business from the consequence of ‘loss of containment’. Applying the 5 elements of Hierarchy of Control – elimination, substitution, engineering controls, administrative controls and even PPE – can lead to the establishment of a clear basis of safe operation (Basis of Safety).

If you would like to discuss how a hierarchy of controls approach can be used to make your facility safe, please contact us on our website, by email info@stonehousesafety.com or call us on 609-455-0001.

Ref 1: https://www.cdc.gov/niosh/topics/hierarchy/default.html