Are you looking for a consulting team that specializes in electrostatic hazards analysis and control? At Stonehouse Process Safety, we can help. Whether you need assistance with evaluating an electrostatic ignition risk or determining the sensitivity of a flammable atmosphere to ignition by any specific electrostatic discharge, we are here to help. Our team of specialists, with unmatched expertise and operational experience, can offer cost-effective electrostatic consulting services and pragmatic advice to issues pertaining to electrostatic hazards and operational problems.

What is an Electrostatic Hazard Analysis?

An electrostatic hazard analysis is a FOCUSED process safety hazard analysis covering the usual examination of likely fuel sources, ignition sources, incident likelihood and consequence, as well as hazard control measures. However, the electrostatic hazard analysis focuses on hazards that can be caused by static charge generation, build up, and discharges.

So why have us undertake such a focused electrostatic hazard analysis?

At Stonehouse we have become aware that most process hazard analysis (PHA’s) and indeed dust hazards analysis (DHA’s) often miss the more subtle electrostatic hazards. Static electricity is a specialist topic that most engineers/ chemical engineers/ process safety professionals have occasionally encountered but have never formally been taught. We bring our experience of performing hundreds of electrostatic hazards analysis, globally and in a wide range of industries, to your facility to enable you to cost effectively identify and control electrostatic hazards.

Understanding Electrostatic Hazards

(Charge, Sparks, and Flammable Atmospheres)

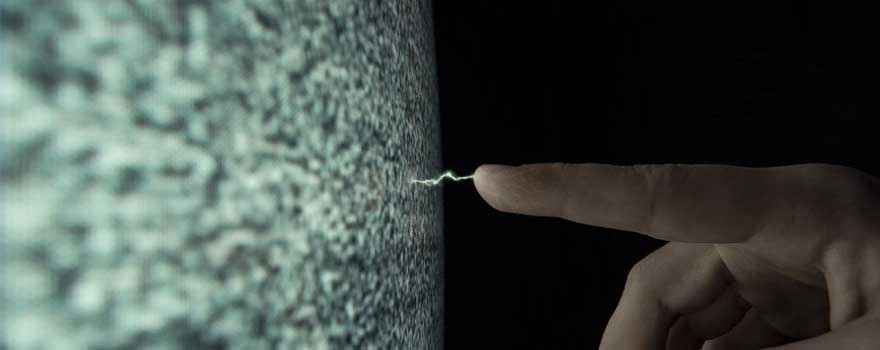

Whenever any two surfaces contact and then separate, static electric charge is generated. In industry, static electricity is generated in many common processing operations, such as when liquids flow through plant or when powder particles contact the surfaces of processing and conveying equipment. So, for example, processes such as powder milling, blending, and pneumatic transfer will frequently generate lots of static charge as will fast, turbulent liquid flow such as at tanker unloading or filtration.

The main concern posed by static electricity in an industrial setting is the risk of fire and explosion due to the ignition of flammable atmospheres by electrostatic discharges. Flammable gases, vapors, powders, and aerosols are common in processing operations and precautions are required to prevent their inadvertent ignition. Precautions against fire and explosion are many and varied, but an approach that should be included is the exclusion or elimination of potential electrostatic ignition sources from locations where flammable atmospheres may reasonably be expected to exist.

There are many precautions that can be taken to control static electricity but before deciding on the most effective way of controlling static electricity on your plant, it’s prudent to first understand how static charge is generated, accumulated, and produces those hazardous ‘sparks’ that we wish to avoid. So, back to basics….

There are several different mechanisms that explain the generation of electrostatic charge. These include contact electrification, double layer charging, induction charging, and corona charging. But by far the most common way that materials become electrostatically charged in practice is through “contact electrification – also known as triboelectrification. Contact charging occurs when any two materials come into contact and then separate.

The generation of electrostatic charge need not be hazardous. However, if static charge is allowed to build-up on items such as plant, equipment, containers, people, powders, or liquids, hazardous electrostatic discharges may result.

Electrostatic discharges occur between two objects or surfaces that are at different electrostatic potentials (voltages). Effective energy of an electrostatic discharge depends very much on the amount of charge accumulated and on the electrical properties of the surfaces/objects that are charged.

Finally, the risk of igniting a flammable atmosphere with a discharge of static electricity depends not only on the effective energy of the electrostatic discharge but also on the sensitivity to ignition of the flammable atmosphere – commonly referred to as Minimum Ignition Energy or MIE. The Minimum Ignition Energy is a (measurable) property of the flammable atmosphere.

What Does Stonehouse Process Safety Provide for Electrostatic Hazard Consulting Services?

Our specialist electrostatic consulting services are designed to help our clients understand, assess, and control fire and explosion hazards as well as any processing problems that might result from the generation and accumulation of electrostatic charge in their processes. Here is a quick look at our services:

- Specialist consulting and on-site electrostatic measurements

- Laboratory testing, including full-scale testing of FIBCs

- Incident investigation

- Expert witness

- Contract research & development

Please feel free to contact us for a tailored practical solution.

Applying Electrostatics | Our Approach

Static electricity can be harnessed for many beneficial uses in a wide array of processes. In fact, there is enormous potential for commercial development. Stonehouse Process Safety has extensive experience in helping our clients design full-scale process equipment, undertake research & development programs, and more. We have been involved in various projects including:

- Fine Coatings

- Liquid Atomization

- Dust Removal

- Powder Manipulation

- Materials Separation

- Powder Deposition

Electrostatic Consulting Services | Industries We Serve

Our engineers and scientists have been serving a diverse clientele both in the United States and globally. Some of the industries that require our electrostatic hazard consulting services include:

- Automotive & Aviation

- Chemicals (e.g. fine, bulk, etc.)

- Coal/Mining

- Electronics

- Energy & Power

- Engineering

- Equipment Manufacturing

- Flavor & Fragrance

- Food & Beverage

- Government Agencies

- Metals & Machining

- Pharmaceuticals

- Pulp & Paper

- Wood

- … and many more!

Choose Stonehouse Process Safety for Electrostatic Hazard Consulting Services Today

The Stonehouse Process Safety team has a long track record of identifying, assessing, and controlling electrostatic hazards in a wide spectrum of industrial processes and situations including liquid and powder handling/processing, rigid and flexible containers for liquids and powders (including flexible intermediate bulk containers (FIBCs)), plastic sheets and liners, material separation and recycling, powder agglomeration and more. Contact Stonehouse Process Safety today to learn more about our expertise in electrostatic hazards, processing problems, and applications!

We also offer virtual process safety training courses such as Exploding dusts, Explosions, Static Electricity and HAC (Hazardous Area Classification). Find out more here.